Länder mit höherem Einkommen verbrauchen ein Drittel der weltweiten Ressourcen.

Quelle: Circularity Gap Report 2021

Media

Thinking in circles

Imagine it is 2050. We have reduced carbon emissions to net zero and averted the worst consequences of climate change. The economy is no longer take-make-dispose but circular. What is life like and how do we get there from here?

Hannah looks through her wardrobe and decides that she will wear her best trousers. They are more than 20 years old, but still in excellent condition because the manufacturer repairs and refurbishes them every year. There isn’t much else in her wardrobe. She leases smart clothing when she needs it, returns other items when they are worn out to be made into new garments, or composts t shirts herself when she’s finished with them – they are fully biodegradable.

The products in her kitchen and bathroom are all in reusable containers. She could not imagine throwing away something as valuable as a plastic bottle. Her home is heated by excess heat from local industry, her fridge runs on reclaimed refrigerant. She 3D prints her breakfast from yesterday’s leftovers and sets off to work on an electric bicycle whose recyclable battery is recharged using renewable energy. Hannah works in a booming sector, developing algorithms that enable precise and efficient sorting of materials after consumers have used them. She does not think of this as waste.

In Hannah’s future, no one would think it normal to throw away anything – clothing, electronics, household goods or food – until the maximum value has been extracted out of it. Materials are kept in circulation for longer by reusing, repurposing, refurbishing and recycling. Products are made for longer lifespans using fewer materials. Instead of acquiring goods, consumers increasingly opt for services to meet their needs.

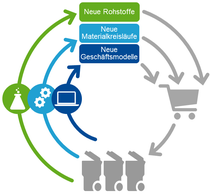

How the circular economy works

More of the goods in circulation are made from renewable sources with a low carbon footprint. What used to be seen as waste is now seen as a raw material. As it has value, it is collected and sorted and does not end up as litter in the environment.

Hannah’s world is a circular economy in which consumption has been decoupled from resource extraction. It is a long way from today’s world, where most waste is landfilled or incinerated, there is more discarded clothing than our systems can manage, electronic waste piles up in cities and plastic litters the oceans. In a world of finite resources, this should not be the picture. To get to Hannah’s world we need to move from our linear economy to one in which we make better use of existing resources – a circular economy.

“The circular economy is a means to three ends: it will help reduce greenhouse gas emissions, preserve biodiversity and tackle inequality,” says Federico Merlo, Managing Director responsible for circular economy at the World Business Council for Sustainable Development, Geneva, Switzerland. In terms of climate change, transitioning from fossil fuels will only get us part way to net zero emissions; we need a circular economy to get the rest of the way. Scaling up circular models of production and consumption will also help restore nature. “With scale comes efficiency,” says Merlo. “Just as renewable energy is now largely cheaper than fossil fuels, so recycled materials will become less expensive than materials from virgin sources and that will translate into lower prices for consumers.

It will take a big change in mindset to a more value-driven attitude toward consumption.

Some end uses have significant societal value even if second lives are unsuitable – like syringes for vaccinations. They will likely be made of reused, recovered or upcycled materials. Products will be designed so that it is easier to recuperate material from them that can easily be reused in the same or other applications. People will dispose of waste into systems that sort and channel materials back into the value chain. Businesses will increasingly collaborate with partners to make that happen.

Creating better jobs

But just as important is the effect the circular economy can have on reducing inequality between countries. “The circular economy enables countries to grow gross domestic product using fewer virgin raw materials and less resource intensity. For emerging economies, it offers the opportunity to grow and create better jobs,” says Merlo. “If a system relies on intolerable labor conditions, that cannot be a sustainable circular economy.”

Perhaps the biggest change will be in our understanding of how we meet our needs and wishes. “It will take a big change in mindset to a more value driven attitude toward consumption, seeing products in terms of where they come from and where they go, and making purchasing decisions on that basis. Businesses will find even better ways of providing services on demand without impacting the environment,” says Merlo.

We need a circular economy to tackle climate change

The transition to a circular economy is already underway and many of the technologies needed to make it work exist. But there is a long way to get to Hannah’s world. Our world is currently only 8.6 percent circular, according to Dutch not for profit organization Circle Economy. And the international sustainability organization Global Footprint Network calculates that providing the goods and services we demand today requires the resources of 1.7 earths. To meet climate goals, we must accelerate the transition to a circular economy. What are the next steps, where are the hurdles and how can we overcome them?

“I once saw people cleaning up waste on a beach. All the time, more waste was coming in with the waves. It struck me that focusing on cleaning up doesn’t work. We need to start further upstream,” says Simon Widmer, Design Network and Creative Lead at the Ellen MacArthur Foundation, Cowes, England.

By “upstream,” Widmer means design. “At that stage, important choices are made about materials and the business model, which are hard to reverse later,” he says. These choices involve understanding the real need and seeing it within the whole system, says Widmer. It might mean not selling a physical product but providing a service or experience. There is no silver bullet. We will need different solutions depending on the context.

It also means thinking in a multidisciplinary way, across value chains. “We need to reimagine the way we collaborate to address the real needs of people. Instead of creating value by extracting resources, we collaborate with a new set of partners to develop solutions that eliminate waste and pollution, circulate materials and regenerate nature,” says Widmer.

Changing consumer behavior

Many sectors are already adopting circular economy approaches, but there are challenges. The textile industry, for example, is a resource-intensive sector with a global value chain that generates a huge amount of waste. With the rise of fast fashion, global apparel production and consumption appears to have doubled over the last 15 years.

“We need to change the way textiles are made, chosen and disposed of, to preserve the value of the materials we put on the market,” says Mauro Scalia, Director of Sustainable Businesses at EURATEX, the European Apparel and Textile Confederation, Brussels, Belgium.

A major challenge is how to get materials back into the value chain after the consumer has used them. EURATEX has launched the ReHubs initiative as an answer to this. “We are creating an integrated system of recycling hubs across Europe,” says Scalia. “This aims at building new partnerships beyond the conventional textiles supply chain and engaging players from the chemicals industry up to retail.”

A further major challenge is price. “Consumers look for cheap products but sustainability has a cost and businesses need to be competitive,” says Scalia. “Most clothing choices are still based on comfort, aesthetics and price.” Although consumer awareness about sustainability is growing, there is still an attitude behavior gap. According to German online clothing retailer Zalando, 60 percent of consumers say they want transparency, but only 20 percent use this information when they make a purchase. Scalia says businesses need to find ways to facilitate more sustainable purchasing decisions and would benefit from clear, harmonized tools to inform consumers.

There are opportunities. “Quality and creativity are how many European businesses differentiate themselves. Sustainability is the new quality,” says Scalia.

For the chemical industry, too, the circular economy brings opportunities, challenges and new partnerships. “Waste companies used to be the people we sent our waste to. Now they are potential raw material suppliers,” says Dr. Cordula Mock-Knoblauch, Director Renewables and Sustainability at BASF’s Intermediates division, Ludwigshafen, Germany.

But whereas fossil fuel refineries produce standardized raw materials, that is not the case for those derived from waste. “We are working with waste companies to figure out the optimal feedstock for our industry,” says Mock-Knoblauch. “Can we use waste that is a mix of materials, or does it have to be sorted?”

Another question is how waste can be transformed into raw materials that easily fit into existing chemical industry value chains. One solution is BASF’s biomass balance approach, where biomass waste is used as a feedstock in the first steps of chemical production. “This approach enables us to increase the amount of renewable raw materials in our value chain more quickly,” says Mock-Knoblauch

Can you really recycle that?

Nuclear waste

Spent nuclear fuel could be recycled to make new fuel for specially designed reactors. The Pacific Northwest National Laboratory in Richland, United States, is working on separating out the usable energy-generating plutonium.

Satellites

There are thousands of bits of orbital debris circling the Earth, including broken satellites. On-orbit satellite servicing is an emerging field that extends the life of space equipment. European aerospace company Airbus is also working on ways to manufacture and assemble in space using disused space objects as a source material to 3D-print new parts.

Insulin pens

People with diabetes rely on insulin pens every day. Most end up in general household waste. Danish pharmaceutical company Novo Nordisk has found a way to separate the materials and recycle them into new products, such as office chairs.

Bigger circles

While individuals and businesses can do their part, policies like the European Union’s Green Deal and Circular Economy Action Plan, or China’s plan to promote clean, recycling-based production methods and green design will also drive the transition. “Individual behaviors can have a tremendous impact. But behavioral change takes a long time, and change has to happen faster,” says Dr. Erika Bellmann, Head of Germany Programs at Bellona, a Norwegian non-governmental organization.

Change has to happen faster.

This is where government comes in. “We need a mix of quotas, norms and bans, as well as incentives and support schemes for new technology,” says Bellmann. “And we need infrastructure – a good waste collection system and electricity from renewable sources. That is important because the bigger recycling loops, such as chemical recycling, can require a lot of energy.”

A circular economy is more complex than a linear one. To optimize it requires tracking and tracing materials, feedstocks and residues throughout their life cycle. This is where digital technology can help to ensure waste streams are of higher purity and quality. “The more we know, the quicker we can close loops and develop more sustainable products,” says Dr. Bernhard von Vacano, Senior Research Fellow at BASF, Ludwigshafen, Germany. It also supports sustainable design. Food packaging, for example, has to prevent leakage, protect the food, be recyclable or biodegradable and economically viable. “Simulation and big data enable us to predict early on which chemistry is likely to deliver all those characteristics,” says von Vacano.

Businesses also need to carry out a life cycle analysis for their products. One part of this involves every actor in a supply chain calculating their carbon footprint and handing the information on to others. “This is the basis for decision-making. That’s why we at BASF are calculating the carbon footprint for each of our 45,000 products. We won’t be able to find longterm sustainable solutions without this knowledge,” says Mock-Knoblauch.

Is it possible to recycle resources forever? “In principle, but the energy required can outweigh the benefits,” says von Vacano. “It is hard to close a loop perfectly. Even if you keep 90 percent of material in the circle, after recycling ten times, only about one-third is left.” Another challenge is that products with a long lifespan will not be available for recycling for many years, so we need to find renewable raw materials to feed into the circles in the meantime.

A circular economy will not be perfect, but the current world is still far from circular. One of the most important drivers of change is personal leadership, says Merlo. “We have seen with the coronavirus pandemic that hidden enemies can bring us to our knees. With climate and inequality, we are facing even bigger challenges. Our leadership is needed now. We should all stop wasting time, because time is one thing that is not circular.”

Related links

Footprint of the circular economy

Gumdrop, a company based in London, England, makes recyclable products from waste.

Discarded chewing gum litters streets all over the world. But we could turn it into something useful. Gumdrop collects chewed gum and processses it into Gum-tec®, a recyclable compound that can be used to make new products, such as the soles of these Stan Smith shoes from German sportswear company adidas. Other products from Gumdrop include pencils, coffee mugs and frisbees.

100,000 metric tons

of chewing gum are produced globally every year.

1kilogram

of gum is used for every four pairs of shoes.

20%

is the minimum share of recycled gum in the Gum-tec®-Material.