0.8 t CO₂e = driving 2,000 miles

Change for climate

A fast-paced environment like the fashion industry can lack transparency throughout the value chain. We believe that this must change since transparency is a strong motivator to drive sustainable sourcing and production and reduce the industry’s overall carbon footprint. Fashion relies heavily on the purchasing decisions of individuals. So, can we answer customers' most pressing questions about sustainable clothing and enable them to trace every step of their shirt's journey, before it arrives in the store?

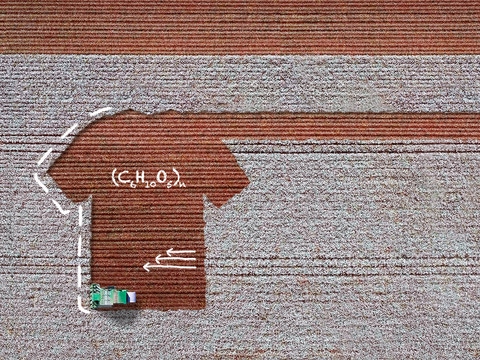

From field to fashion show: The fashion show – held on a grower´s farm near Komotini – featured clothes made entirely from the cotton produced in the CSF program.

We asked ourselves: Is it enough to simply provide farmers with high-quality FiberMax® seeds for producing sustainable cotton? Or could we track responsibly sourced and sustainable inputs in both clothing and textiles while also meeting the needs of every stakeholder? Our passion for real change made us think further. BASF cotton experts and farmers worked together to create two revolutionary programs that allow growers, ginners, manufacturers, brands, and fashion producers access to a digital platform that traces every cotton bale from field to finished product. Rewarding sustainability measures offers further incentives to switch to sustainable methods and choices. We made it our mission to connect the whole cotton fiber supply chain and make every step along the way transparent and traceable – from field to fashion.

The benefits for farmers and consumers alike are numerous. We now have the data to answer consumers’ questions. At the same time, we’re able to give back to farmers. It really is a win-win situation.

In 2018/2019, farmers grew more than 27 million tons of cotton (FAO, 2021 “Recent trends and prospects in the world cotton market and policy developments of cotton”). How can we establish a basis for real change in such a huge industry? How can we make sure that our sustainable approach, paired with technology, becomes a real benefit for millions of growers worldwide rather than an inconvenience? Cotton farming supports 100 million families across five continents. Major producers like China, India, the United States and Brazil are well known,but not a lot of people know that 85% of the cotton fiber farmed for the EU is grown in the Northeast of Greece. So, we began our groundwork for lasting sustainability and reducing CO2 emissions in two major cotton farming regions – Greece and the US.

Quality, sustainability, and transparency are at the heart of the cotton programs we have developed. The “Certified Sustainable FiberMax®” (CSF) program in Greece and the “e3 Sustainable Cotton” initiative in the US both start with premium BASF cotton seeds. The emphasis of both initiatives, supported by innovative technologies, is to produce sustainable fashion and socially conscious products. Cotton farmers working with BASF are committed to making a change together. On top of tracking their production, they are implementing sustainable practices. In a 2-year program in close collaboration with the University of Thessaly in Greece, we are comparing these sustainable cotton cropping systems to conventional ones. The 2022 results show that these practices can reduce CO2 emissions by 5-15% and potentially fix 60 - 80 kg of soil organic carbon per hectare each year.

The percentage of reduced emissions represents an estimated benefit of 0.8 tons of CO2 equivalent per hectare annually, corresponding to 2,000 miles (3,219 km) driven by an average gas-fueled passenger vehicle (Source EPA: Green Gas Equivalencies Calculator).

We believe the right path to lasting sustainability is through constantly measuring and optimizing seeds and farming practices. To truly understand the impact each step has along the cotton supply chain and to ensure measurable success across the process, we split the data collection into assessable steps and partnered with farmers to establish a reward system for using digital platforms and tracking their production.

The demand for quality Greek cotton fiber is very high. BASF has already teamed up with around 1,600 farmers who buy BASF FiberMax® seeds. Farmers are paid a premium for collecting data about the cotton from the ginners. The blockchain farmers will receive an additional reward based on the amount of cotton used each year from blockchain partners. This groundbreaking technology makes it possible to track and trace every seed planted through every step of the process to the finished shirt.

Farmers in the e3 program in the U.S. track specific on-farm environmental and social measures. These are documented on a digital platform, for textile manufacturers and customers to trace every individual cotton bale. Additionally, BASF works with brands to incentivize the farmers’ sustainability efforts. The e3 program is named after the way farmers are committed to growing cotton: socially equitable, economically viable and environmentally responsible, all of which are certified and verified through independent audits.

Aeiforki, the implementation partner for the CSF program, conducted a carbon footprint study in 2023. The carbon footprint of 2.2 pounds of cotton fiber is 13.80 pounds of CO2 equivalents which corresponds to driving 16 miles (25km) or charging 761 mobile phones.

Sustainably produced cotton is expected to be the norm for most fashion brands by 2040. While the roadmap for this change is already laid out by the United Nations Sustainable Development Goals, there is also a new and growing global trend for sustainable cotton sourcing. We want to provide an international platform for cotton farmers to share their sustainability experiences, triumphs, and the work they’re doing to advance those UN SD Goals. In 2023, a delegation of US and Greek farmers and ginners representing both the “e3 Cotton Program” and the “Certified Sustainable FiberMax® program” will join BASF at a round table event at the United Nations Headquarters in New York.

Farming is getting bigger and more complex – it is the biggest job on earth. That is why we are changing sustainable cotton for a better future.