Media

Collaborating for a circular economy

BASF secures funding from DOE for four plastics-recycling research projects.

It takes a village to develop useful plastics that improve our everyday lives – and at the same time make them more reusable, biodegradable.

For this reason, chemical company BASF teamed up with various universities, U.S. National Labs, and corporations in submitting eight proposals to the Department of Energy (DOE) for help in bringing some of its latest research on bio-based and biodegradable plastics to fruition.

The government agency approved four of those proposals as part of the development of energy-efficient recycling technologies to help reduce nationwide plastic waste in the environment. The four successful projects were awarded a combined $8.6 million in funding.

“This is the first time we’ve done anything on this scale with this many awards from one grant opportunity,” said Christopher Hewitt, Ph.D., Innovation Network Manager, BASF, who was at the forefront of submitting the proposals to the DOE. “[BASF’s] European colleagues have a long history of working with European funding agencies to secure funding, but we haven’t done it so much in the U.S.”

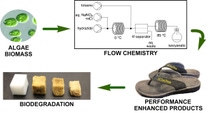

The four projects include: 1. The production of high-performance biodegradable polyurethane products made from algae precursors; 2. Degradable biocomposite thermoplastic polyurethanes; 3. Hybrid approach to repurpose plastics using novel engineered processes (HARNESS); and 4. Recyclable and biodegradable manufacturing and processing of plastics & polymers based on renewable branched caprolactones.

BASF scientists are supporting research on two of those projects and serving in a technical advisory capacity for the other two.

.jpg)

One might wonder, why did a chemical company decide to turn to a government agency for help with plastics-recycling projects? For one thing, sustainability has been one of the highest priorities at the company for a long while. This concept is embedded in BASF’s corporate purpose – creating chemistry for a sustainable future. The same thing goes for a circular economy. By 2025, the company aims to process 250,000 metric tons of recycled and water-based raw materials annually, replacing fossil raw materials. Secondly, these projects tend to be long term and costly. While the company is investing money of its own, it’s always helpful to receive support and validation from a tax-funded government agency.

“We are doing work in these areas anyway, and what these partnerships do is enable us to leverage the money that we’re investing in ourselves for collaboration, which increases the quality and quantity of innovative ideas.” Hewitt added, “These projects are bringing the best minds that we have alongside the best minds outside the company so that we can drive the solutions forward.”

While everyone involved in the projects is hopeful, they are also aware of the challenges ahead. Ending plastic waste is easy to talk about but very difficult to achieve and no one knows that better than Joshua Speros, Ph.D., Innovation Manager, BASF, who liaises between BASF and California partner universities and supported two of the awarded proposals.

“The plastic industry grew out of the fossil fuel industry and has been established for over 100 years. Our success here has made introduction of new, bio-based or recycled plastic materials a challenge,” said Speros. “You’re also trying to change the end user’s perspective and behavior around plastics – it’s quite hard. You have the financial and human elements to compete with, but we’re optimistic for the future.”

All four of the BASF-involved research projects are currently in phase 1 – the planning stage, but everyone involved is eager to move to the next phase of conducting research for a better plastic future.

“[The collaboration] has enabled us to come together with other bright minds to creatively explore solutions to this really important sustainability challenge,” Hewitt concluded. “I hope that leveraging our contribution to attract public funding will enable us to find something that really works.”

To learn more about each of the DOE-funded projects with which BASF is involved, click here.

Published on April, 9, 2021, by Anna Spiewak.

For media inquiries or to repurpose this article, please contact Lisa Brown.