Dual Protection for an Enduring Future:

A Solution for Rising Damp and Efflorescence

BASF is excited to present our cutting-edge dual protection system that addresses the challenges of rising damp and efflorescence. This innovative solution offers multiple layers of security, ensuring exceptional durability for your wall system. By combining 2K cementitious of Acronal® 7802 and 1K mastic protection of Acronal® 7801, BASF provides comprehensive defence against the damaging effects of moisture. With this breakthrough technology, you can have peace of mind knowing that your walls are protected from the inside out.

The cause of rising damp and efflorescence

The construction industry has long struggled with the challenges of rising damp and efflorescence. These issues typically occur in walls where water infiltrates from below or from surrounding areas, such as basements, kitchens, or bathrooms.

As moisture moves through the concrete, it carries salts that deposit on the surface, causing efflorescence and damaging the coating. This not only leads to an unsightly appearance but also creates a conducive environment for mold and fungi to grow, compromising indoor air quality and creating uncomfortable living conditions.

Moisture seeps through the concrete, carrying salts that accumulate on the surface, leading to efflorescence and compromising the integrity of the coating

The traditional solution for tackling rising damp and efflorescene

The market has traditionally relied on solutions such as 1K mastic waterproofing or injection systems to address rising damp and efflorescence issues. However, these methods often fall short of delivering long-lasting solutions, and problems tend to persist even after application. In some cases, injection applications can be complicated, leading to further frustration and expense.

A breakthrough long-term solution from BASF

BASF has introduced a game-changing solution: a combination of 2K cementitious layer with a 1K mastic layer, to provide prolonged durability of your wall system.

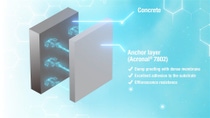

Anchor layer - 2K cementitious membrane with Acronal® 7802

The first protection comes from 2K cementitious waterproofing with Acronal® 7802. It is called the “anchor layer” as Acronal® 7802 provides the necessary adhesion of 2K cementitious waterproofing to the concrete wall. This dense membrane provides a barrier against rising damp and salts that migrated from behind (negative side).

Seal layer - 1K mastic membrane with Acronal® 7801

The second layer is called “seal layer”, using Acronal® 7801 as 1K mastic waterproofing. The membrane using formulated Acronal® 7801 bonds well with the Anchor Layer while having a high degree of elasticity to give crack resistance. It also has high water resistance to withstand disturbance from the positive side of the wall.

It's important to note that all the layers of Acronal® 7802 and Acronal® 7801 are breathable, meaning that they have excellent water vapor transmission properties. This ensures that any moisture trapped within the substrate can escape while at the same time blocking the passage of salt deposits.

Tests prove it works

Our laboratory testing has demonstrated the distinct benefits of Acronal® 7802 and Acronal® 7801's dual protection system against rising damp and efflorescence. Our commitment to ongoing testing and research ensures that we continue to offer our customers the highest level of performance and protection for these challenges.

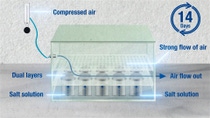

Test #1 – The effectiveness of blocking efflorescence

To ensure our solution can effectively block efflorescence, we conducted a lab test that simulates salt with moisture movement, which prompts efflorescence on the wall. We incorporated air flow inside the device, thus creating a more extreme condition of salt movement to the surface. The results show that BASF's dual protection system effectively resists efflorescence, while the market benchmark fails to do the necessary.

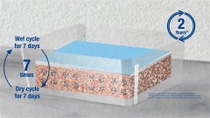

Test #2 – Durability of dual protection system

Here, we observe the durability of the dual protection system, using a 7-day wet and 7-day dry cycle test using a salt solution. These cycles are repeated seven times, giving a harsh condition that mimics acute rising damp situations for prolonged periods. BASF's dual protection system shows resistance to withstand the harsh cycle and durability test, while the market benchmark shows ineffective protection.

Information was derived from simulation data based on our current knowledge and experience as of Q2, 2023. Actual job site conditions may vary. Information stated herein should not be relied upon to satisfy from your obligation to undertake your own inspections and evaluation. Please carry your own tests for providing an accurate guarantee period to end customers. All liability relating to the information herein is expressly disclaimed. Any information, including but not limited to descriptions, drawings, photographs, data, proportions, weights etc., provided herein can be changed at BASF´s sole discretion anytime without prior notice and do not constitute the agreed contractual quality of the product. BASF rejects any obligation to, and will not, automatically update this document and any information provided herein, unless required by applicable law.