Change for climate

Making the most of waste

In thirty years from now, humanity will generate 70 percent more waste than it already does today. That’s a grim forecast for the global effort to achieve climate targets. How can we turn this around for a more planet-friendly future? We are strengthening our efforts to use recycled and renewable raw materials in production. And we’re taking it a step further by finding new uses for BASF binders, so upcycled products can be created almost entirely from waste!

Get creative: Breathe new life into waste products

Turn old items into something new! The trend of re-loving outdated possessions and giving them a second chance is well established. Perhaps you've already refurbished a piece of furniture or revived clothing items to save them from landing in the trash. But what if we could eliminate waste altogether – or transform it into new products – on an industrial scale?

Strong bonds: Technologies to save resources

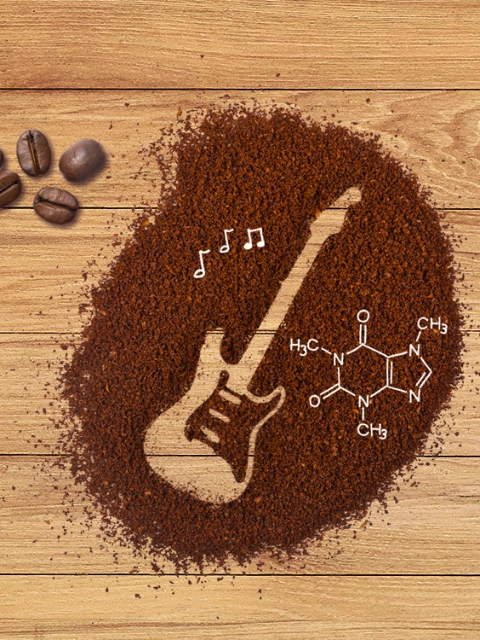

Together with industry partners, BASF is developing ways to transform reclaimed materials, like denim and clothes, and discarded materials, like spent coffee grounds, brewer’s grains, used paper cups and chopsticks, into tables, flooring and even guitars. What sounds like a dream for the future is facilitated by a process that uses binders to merge small particles of waste materials and turn them into strong, stable composites. BASF’s low-emission fiber bonding technologies Acrodur®, acForm® and Acronal® will not only enable our customers to reuse end products, but also to convert them into higher-quality items – a classic example of upcycling.

Waste is something we all have in abundance – so why not make something new out of it? Upcycling is a great way to turn waste into important raw materials and reduce our dependence on wood. With our BASF binders, we can not only give waste products a second life but help to protect the climate.

The result: Waste as a game changer for climate protection

While the fight for resources is just beginning, waste already exists everywhere. BASF fiber bonding technology can help limit our dependency on precious natural resources, such as wood. But reusing waste not only relieves the pressure on our forests: Upcycling also helps us reduce CO2 emissions by extending the life of single-use materials and minimizing the amount of new raw materials entering production cycles. In addition, upcycling reduces the amount of trash that ends up in landfill or incineration.

Upcycling: A valuable contribution to the circular economy

In a circular economy, materials are recycled in closed production loops. With upcycling, on the other hand, waste products are not only reused but also transformed into higher-value products. If materials cannot be recycled within the same production process, upcycling can be a valuable and important contribution to the circular economy. Both processes offer industry the opportunity to process waste into raw materials to manufacture new products.

Fiber bonding technologies are the key to upcycling and, for example, turn coffee grounds into coffee tables.

Our promise: Creating chemistry for a sustainable future

Sustainability is an essential part of our core identity at BASF. That is why we want to take upcycling to the next level with our binders. Although the project is still in the pilot phase, the great potential of this method for recycling industrial waste is already clear. And it’s not only designer furniture that can be made from waste with our binders, but high-quality floor coverings, and even musical instruments. It is often said that one person’s trash is another person’s treasure – now there’s an opportunity to transform industrial-scale waste into a wealth of climate-friendly treasures.