Technical Services

Proven technologies for demanding applications

SLM and LMD are part of our world

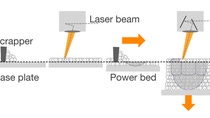

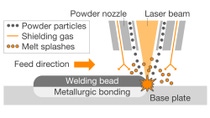

We work with powder-based technologies. Selective Laser Melting (SLM) and Laser Metal Deposition (LMD) are the two most important methods. The Additive Manufacturing Center at BASF has state-of-the-art systems on an area of 800 square meters, as well as four 3D printers with an available building volume of up to 400 millimeters in the cube. We apply and comply with the highest safety standards by housing our equipment and working with metal powders to prevent contamination and ensure the health of our employees.

Post processing of functional components is absolutely essential. Alongside additive manufacturing, we therefore also provide a comprehensive portfolio of conventional processing technologies in the BASF specialist centers.