Change for climate

A positive balance for the climate

Did you know that the ingredients in your detergents or dishwasher tabs could help reduce CO2 emissions? Many ingredients in everyday products can be derived from fossil fuels, such as crude oil and natural gas, or from renewables. Now, in a joint commitment with Henkel, BASF’s biomass balance concept is being used to increase the amount of renewable raw materials used in the manufacture of ingredients for their laundry and home care products, as well as their hair and body care products.

The idea: scaling up renewable resources

Consumer awareness of climate protection is already high and demand for products and services with a lower impact on the planet is rising. But key ingredients in many everyday products are still derived from limited resources such as petroleum, crude oil, or natural gas. That’s one reason why BASF has launched the biomass balance approach.

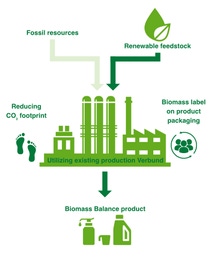

We substitute fossil-based raw materials in our production chain with the equivalent amount of renewable feedstocks, such as bio-naphtha and biomethane. These organic raw materials are produced from organic waste such as leftover food, vegetable oils, agricultural waste and crops. The renewable feedstocks are then attributed via the biomass balance approach to a wide range of BASF products, including superabsorbents, dispersions, plastics, surfactants and intermediates. This approach helps protect the environment without compromising on the high-quality our customers and consumers expect.

Increasing the amount of renewable raw materials used to make ingredients for products from Henkel’s core consumer brands will reduce around 200,000 metric tons of CO2 emissions compared to conventional ingredients.This is roughly equivalent to an airplane flying 76 times around the world.

The collaboration: cooperation for the climate

Henkel, a leading global producer of laundry and home care products, and hair and body care products, is one of our customers that has embraced the biomass balance approach. The four-year collaboration with BASF will increase the amount of renewable raw materials used to manufacture ingredients for products from Henkel’s core consumer brands such as Somat, Perwoll, Schauma, Gliss, Syoss, Fa and Persil. Compared to conventional ingredients, the renewable-based ingredients will reduce around 200,000 metric tons of CO2 emissions.

In January 2022, after a successful pilot, BASF and Henkel started to replace fossil-based raw materials at scale for around 110,000 metric tons of product ingredients per year.

The collaboration covers most of the ingredients for Henkel’s hair and body care ranges produced in Europe, as well as ingredients for laundry detergents and dishwashing products.

To ensure that the equivalent amount of renewable materials is actually sourced and used by BASF for the production of Henkel ingredients, the biomass balance process is independently audited according to the REDCert2 certification scheme.

BASF´s certified biomass balance approach

The biomass balance approach replaces fossil-based raw materials in our production processes with renewable feedstocks. These alternative feedstocks are attributed to customer products via the independently certified mass balance method. The process is similar to renewable electricity generation.

Electricity grids are supplied with electricity from both conventional sources and renewable energies. Customers who purchase renewable electricity don’t know whether the energy they use is from a renewable or a conventional source, but they can always be assured that the amount they have financed will contribute to reducing CO2 emissions. The same principle underlies our biomass balance approach.

BASF's biomass balance approach gives our customers the ingredients they need to make products with a lower carbon footprint compared to conventional products. Henkel shares a similar vision on sustainability, and they were a courageous partner to launch the biomass balance approach at that scale. This collaboration supports their ambitious climate protection strategy and is contributing to a more sustainable future for manufactured goods.

Passion for change: a matter close to the heart

Change for climate at BASF is only possible through the dedication of every person involved, especially when it involves products that so many people use every day. Our team members were eager to find the first Henkel products with information about the biomass balance process on the packaging.

The journey continues

It is not only Henkel that benefits from the BASF biomass balance approach, but every customer that chooses to move from fossil-based to renewable-based raw materials, whether they are in construction, food packaging, furniture and flooring, the automotive industry, and the household and personal care industries. By continuously increasing the share of sustainable feedstocks via the biomass balance approach, we are making a strong contribution to more sustainable sourcing and helping to shift our raw materials away from fossil resources.