Technical Services

Additive manufacturing meets process engineering

BASF – rich history in process development

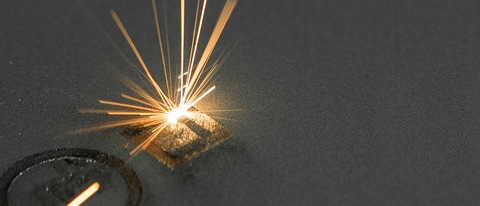

We push the boundaries of process technology since 1865. We produce the components required for this in our own workshops in line with the highest demands on quality. As a driver of innovation in the chemical industry, we not only rely on conventional processes for manufacturing equipment, valves and control components, but also deploy the latest technologies, benefiting from their advantages for the complex applications in the chemical process industry. This includes additive manufacturing. We have been qualifying metal components using our own additive manufacturing machines and applying our own expertise since 2015.

Our AM philosophy

The focus is on the application. Additive manufacturing makes sense wherever it increases the performance of the applications, optimizes processes or ensures the availability of key components. And, throughout all of this, we set the highest demands for quality for ourselves. We produce the components in-house and use them in our chemical plants.

Verified and certified

In mid-2019, we were the first company to carry out a certification process according to the Pressure Equipment Directive, including procedure qualification testing, for a pressure equipment component made using a 3D printer.

Metal Additive Manufacturing of a Coffee Bean Embossing Plate

From real coffee beans to an additive manufactured embossing plate: It’s all about creative ideas! BASF’s metal additive manufacturing team accepted the challenge from BASF’s Dispersions & Pigments division – and created a metal coffee bean embossing plate. It now helps to meet customer demands by creating detailed surface structures on wood fiberboards. Check out the process of 3D scanning and additive manufacturing!