BASF in Greater China 2022

Occupational safety

- Cultivating a safety culture through diverse activities and digital campaigns

- Optimizing the Permit to Work System according to the latest national standards

To create a safe and secure work environment, we encourage risk-averse behaviour and safe working practices. Based on our expertise, we are constantly refining and enhancing our requirements and training.

In 2022, BASF launched the Global Safety Days (GSD) campaign with the slogan “Think safety, act safely!” in Greater China. More than 200 safety activities were carried out both online and offline to increase our employees’ knowledge and awareness. Over 16,000 BASF employees and contractors in Greater China participated in this campaign.

The annual “Greater China EHS Awareness and Knowledge Competition” (GEAR) program was held for the third time to promote the safety culture among employees. Over 3,100 BASF employees and contractors took part in this self-learning and interactive program. More than 2,400 participants joined the online competition across Greater China. BASF GEAR (Campus), an online competition that was launched in 2022 on EHS knowledge, drew more than 200 students from four Chinese vocational schools.

The timely optimization of our work permit system is critical to ensuring compliance with the new national standard (GB30871-2022), which stipulates the safety criteria of special work in hazardous chemicals firms in Greater China. An online workshop was organized to introduce the latest national standard codes, and a working group was set up to optimize the work permit system to meet the new regulation.

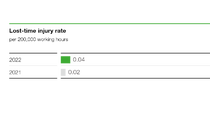

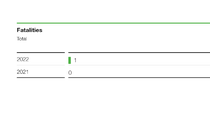

By 2025, BASF hopes to reduce the global lost-time injury rate to less than 0.1 per 200,000 working hours. In Greater China, we recorded 0.04 work-related lost-time injuries per 200,000 working hours in 2022. Unfortunately, there was one fatal work-related accident in 2022. At the Changsha site in Hunan Province, an employee suffered fatal injuries while performing cleaning activities.

At BASF, safety is our top priority. We do everything we can to prevent accidents, review the relevant processes of each case, and use our findings to take appropriate measures to prevent them from happening again. These include regular campaigns and training aimed at increasing staff safety awareness and improving safety operations.

Starting 2023, there will be changes in the incident reporting whereby BASF will report the High Severity Work Process Related Injury Rate (HSIR) with a target of 0.05 until 2030. This will be the main Key Performance Index (KPI) for Occupational safety incident management steering purpose and the aim is to focus on high severity incident to create more awareness to avoid incidents with high consequences.

.jpg)