BASF Corporate Commitment

We produce safely and efficiently.

.jpg)

BASF in Greater China 2022

Health and Safety

Our first priority is to protect both people and the environment. Our core business – the development, production, processing, and transportation of chemicals – necessitates a responsible approach. We address environmental, health and safety risks with a comprehensive Responsible Care® Management System. With this system, we expect our employees and partners to understand the potential hazards of working with our products, substances and plants and handle them appropriately.

BASF Corporate Commitment

We produce safely and efficiently.

Product stewardship

BASF is dedicated to minimizing the negative effects of our products on the environment, health, and safety while optimizing performance. This commitment is enshrined in our Responsible Care® charter. We ensure that our products do not pose any risks to humans or the environment when used responsibly.

We have put in place internal guidelines and comply with all relevant national and international laws to ensure high levels of product safety around the world. The Environmental Protection, Health, Safety and Quality unit in the Corporate Center conducts regular audits to guarantee high standards of product stewardship.

We subject our products to a variety of tests and assessments in order to uncover potential harmful qualities or dangers to health and the environment before releasing at an earlier stage. This is to ensure that necessary measures and recommendations are in place at every stage of the product lifecycle. We give easy access to information and related hazards of our products to those who buy, sell, use, transport, or dispose them using the Globally Harmonized System (GHS), which is used to classify and mark our products globally. All the relevant information is managed via a global database.

Various regional and national chemical restrictions have evolved in recent years. We share our expertise and make helpful recommendations for regulation formulation and implementation in China with local authorities.

Process safety

Process safety is a core part of ensuring safe, effective, and sustainable production. We adhere to stringent safety standards in the planning, construction and operation of our plants around the world. Our global guidelines provide the framework for the safe construction and operation of our plants to guarantee the safety of people and the environment. The safety concept developed by our experts for each plant considers the key aspects of safety, health, and environmental protection – from the initial design of plants to the end of the production phase – and sets out specific safety measures. Regular implementation checks are carried out to ensure that all processes comply with the safety concept and are always up-to-date.

Extensive mitigation plans are well-designed, particularly for hazardous materials in storage, reactivity, and physical processing in operations, as well as energy management. To ensure the highest level of safety at our plants across their entire lifecycles, we make sure that our protection concepts, safety reviews and resulting safety measures are carried out in all our plants at timely intervals based on potential risks. Our plants’ safety and security concepts are updated on a regular basis by taking account into new technologies and regulatory developments. In 2022, we began monitoring and assessing newly published process safety norms and standards on a monthly basis to guarantee that all BASF locations in China fulfill local requirements.

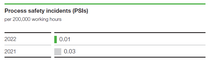

Process safety incidents (PSI) are a critical performance indicator. BASF’s global target is to reduce the safety incident rate to less than 0.1 per 200,000 working hours by 2025. The PSI rate in Greater China was reduced to 0.01 per 200,000 working hours (2021: 0.03) in 2022.

This achievement can be attributed to the Process Safety Incident Reduction Program, which focuses on the continued improvement of incident management by investigating all safety incidents, analyzing root causes, and implementing adjustments as needed.

To continuously improve process safety performance, a number of initiatives were taken in China, including the conduct of the Environment, Health, and Safety (EHS) review, the Pre-Startup Safety Review (PSSR), and the Responsible Care audit. To further enhance the expertise of our colleagues, custom-made process safety workshops and training on topics such as Management of Change (MOC), PSSR and local regulation updates were organized. We continue to adopt a globally uniform strategy to manage changes in regulatory requirements in order to constantly improve the identification and control of risks at plants.

Prompt emergency response with extensive preventive measures

BASF strives to avoid safety-related incidents as much as possible. We have implemented preventative measures with clearly defined responsibilities and procedures at all sites. A highly skilled emergency response team reacts quickly to any incident that occurs in operations, transportation, or along the supply chain.

BASF Greater China’s first turbo-jet combined foam fire truck went into service at the Caojing Site

Throughout 2022, we organized emergency response training and drills based on real scenarios in a variety of forms at our sites in Greater China. BASF Greater China’s first turbo-jet combined foam fire truck also went into service at the Caojing site, further boosting the site’s capability to handle incidents and emergencies.

Shanghai Pudong Innovation Park has been recognized for best practices in firefighting management for six consecutive years

We continued to contribute to emergency and standard formulation in Greater China. Shanghai Pudong Innovation Park has been recognized for the best practices in firefighting management for six straight years largely due to BASF's exceptional firefighting management.

Security

We protect our employees, sites, plants, and proprietary information from unauthorized access. Cybersecurity and information security play an increasingly important role. The “security by design” principle is applied to critically review and optimize IT applications from a cybersecurity perspective throughout the application development phase. We take various measures, including providing training programs to our employees, to increase our capability to prevent, identify and react to security incidents. BASF’s group-wide recommendations for information protection were also updated in line with the latest developments in 2022.

To improve awareness of security threats, we scheduled mandatory online training for all staff. Cybersecurity has become increasingly important, especially for those who work from home. The training was also designed in different formats, such as seminars, case studies, and interactive training. In 2022, around 58,000 BASF Group employees, including 5,300 from Greater China, completed basic cyber security and information protection training.

Another important aspect of security is site security. Our security teams handle everything from site access controls to protection from industrial espionage. Potential safety and security hazards are routinely considered for all investment projects and strategic initiatives. The basic premise is to identify potential risks early on, assess them properly and devise appropriate safeguards.

.jpg)