Media

Pigments & Color Innovation in the Automotive Industry

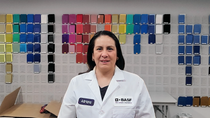

Born and raised in Mexico City, Adriana Pullin grew up in a traditional family. As a child, she was curious about how things worked and understanding the ways of the world. After high school, Adriana chose to study chemical engineering with a minor in polymers at the National Polytechnic Institute in Mexico.

She joined BASF in 2005 and, in 2016, relocated to Southfield, Michigan, where she currently holds the position of Pigments and Innovative Colors Leader for North America. Adriana shares her story and love of color below.

How did you first get involved with automotive coatings?

I took an extra class during my university studies, which was in a polymer lab. In this polymers class, part of the curriculum was dedicated to thermoplastics, which dived into the different kinds of coatings and the performance they should have, and I was really interested in it.

I started looking for a job soon after, and coincidentally, I came across one in refinishes. They hired me as an apprentice, and I earned credits for school at the same time. There, I learned color theory, how to formulate to improve endurance and certain characteristics of coatings and how pigments affect color. As a car fanatic myself, I was also thrilled to see models before they came into the market. In an effort to match the colors of the cars coming out, dealerships allow you to see the brand-new cars, see the colors and then formulate them in the lab and reproduce them in production. I felt like I was changing the world and that I could do anything.

Once I finished my initial contract, I decided to continue on as an employee for two more years. And after that, I joined BASF and never left.

You are the Pigments and Innovative Colors leader in North America. What does your role entail?

I am responsible for pigment activities in North America (U.S., Mexico and Canada). Essentially, to create color, our coating bases need to have pigments on them. Pigments are particles that can either bring color or create specific effects. There are three types: particles that provide color; aluminums, which create a more metallic look; and glass flakes, organic or synthetic structures that provide additional effects.

At BASF, we meet with suppliers and select from their pigment portfolio based on our needs and the needs of our customers, and together, we can also develop new pigments. My team handles all the qualification and testing of the pigments we select to make sure they meet the specifications required, for example in terms of durability or stability.

Another part of our work is color innovation. We create colors with pigments nobody has ever seen before; we create colors with new features our competitors have not yet developed and that can be profitable for the company.

Color innovation can also involve sustainability. For example, some colors are traditionally sourced from petroleum. However, it is possible to obtain pigments from more sustainable sources, reducing carbon emissions significantly, and this is something we are also working on.

As part of your work, you are also teaching a seminar on behalf of BASF. What has this experience been like for you?

BASF offers a color science seminar at Eastern Michigan University and the Detroit Color Council. The person who used to teach these seminars retired a year ago, but before leaving, he gave me all the materials he used. In 2023, I got to teach one of the two classes with him and one more by myself. Funnily enough, I took this exact same seminar with him ten years ago to learn about color science, and I never thought I would be the one teaching it now.

It is a great experience because it helps me understand how color science plays into other industries and it provides tools that can be adapted to automotive. The questions students ask are also great motivators; they help me think and question things myself. It is so rewarding to be able to teach someone else something, share ideas, and see them engage with you and enjoy the lessons. It left me feeling energized and refreshed.

What are the biggest challenges you face in your job today?

The biggest challenge is creating things that are not there yet. When somebody asks for a pigment with a functionality that has never been achieved before, you have to look for alternatives. You don't have a straightforward response.

Two other important challenges are also predicting coming trends and finding the best way to incorporate new technologies. For this reason, we are continuously improving our global strategy and processes so we remain agile and innovative.

I speak daily with my counterparts from Asia Pacific and Europe, and we all report to the same person. Sometimes we have varying opinions, and the interests of each region may not always align, but we work much more efficiently. Having such a diverse team also provides more learning opportunities, a chance to be creative and to grow as professionals, honing our problem-solving and communication skills.

What is your role in BASF’s Automotive Color Trends collection?

Each region has its own Pigments and Innovative Colors leader as well as color design leads. Every year, the design leads from all three regions come together to develop the concept behind each new color trend collection, and my counterparts and I do the laboratory work for them.

Designers do their own research, looking at fashion, furniture, language, etc., and then creating a global strategy around the collection (innovation, individuals, sustainability, etc.). Once the concept is created, we decide together which colors will go into the different aspects of the collection and the regions, the aspects each color should have (for example, more transparency and lightness). It's really fun because it opens your mind and helps you think outside the box.

For questions, please contact mariana.licio@basf.com.

For media inquiries, please contact molly.birman@basf.com