Sustainability

New technologies

Basic chemicals such as hydrogen and methanol are responsible for around 70 percent of greenhouse gas emissions of the european chemical industry – but they are also the indispensable starting point for all the innovative products that enable our customers to protect the climate and that make our everyday lives easier. That is why our research focuses on basic chemicals.

We still have a long way to go. But we are optimistic that technologies such as methane pyrolysis or the electrification of the steam cracker will enable a transformation to low-CO2 chemical production.“

Dr. Andreas Bode, Project manager Carbon Management R&D program

The most important climate-friendly technologies on which BASF is working at full speed include the electrically heated steam cracker furnace for the production of basic chemicals and processes for the production of hydrogen such as methane pyrolysis and water electrolysis. Clean hydrogen is a key to the success of the transformation toward climate-friendly chemistry, mobility and heating.

Electrically heated: steam cracker furnace

More

Fossil fuels represent the largest sources of CO2 in the chemical industry because chemistry requires energy. To split naphtha into olefins and aromatics for further processing, BASF’s steam crackers need to reach a temperature of 850°C. Until now, the cracker’s furnaces have been fossil-fired, meaning they are operated with natural gas.

If we could operate these crackers with electricity from renewable sources instead, this would reduce the CO2 emissions by 100 percent during the heating process.

BASF, SABIC and Linde have signed a joint agreement to develop and demonstrate solutions for electrically heated steam cracker furnaces. The partners have already jointly worked on concepts to use renewable electricity instead of the fossil fuel gas typically used for the heating process. With this innovative approach focusing on one of the petrochemical industries’ core processes, the parties strive to offer a promising solution to significantly contribute to the reduction of CO2 emissions within the chemical industry.

This technology leap will be a milestone on the path to a low-emission chemical industry. We have not only developed the world’s first electrical heating concepts for steam crackers, but also want to demonstrate the reliability of key components for use in this type of high-temperature reactors. To be able to drive a timely scale-up and industrial implementation of this technology, investment support and competitive renewable energy prices will be important prerequisites.”

Dr. Martin Brudermüller

Chairman of the Board of Executive Directors of BASF SE

Climate neutrality with clean hydrogen

More

For BASF, the use of clean hydrogen is a key element in reducing greenhouse gas emissions. In Europe, for example, BASF is one of the largest hydrogen producers. At our main plant in Ludwigshafen alone, we produce around 250,000 metric tons of hydrogen per year. The gas is a key and irreplaceable raw material for important products such as ammonia and is found in many consumer products from chewing gum to plastics. Hydrogen is mostly produced from hydrocarbons such as natural gas by steam reforming, which involves high CO2 emissions (about 9 to 10 tons of CO2 per ton of hydrogen). This makes hydrogen production one of the largest CO2 emitters in the chemical industry.

In order to produce hydrogen without CO2 in the future, BASF is relying in parallel on two processes: commercially available water electrolysis and methane pyrolysis, for which BASF is developing a new process technology. In order to further expand CO2-free hydrogen production, sufficient electricity based on renewable energy must be available

While hydrogen is used as a material in the chemical industry, it can be used as an energy carrier (mobility, building heating) in other areas of application. Since low-emission hydrogen is in short supply, it needs to be prioritized for those areas in which its use is essential.

Find more about hydrogen here

Clean hydrogen: Methane pyrolysis

More

The chemical industry needs large quantities of hydrogen. For instance, BASF uses it as a reactant for ammonia synthesis. Because hydrogen is indispensable for carrying and storing energy in numerous sustainable future applications, it will continue to grow in importance.

Steam reforming is currently the most important industrial-scale procedure for producing hydrogen from natural gas or coal. However, this process releases considerable quantities of CO2.

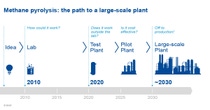

As part of its Carbon Management program, BASF is working together with cooperation partners in a project funded by the Federal Ministry of Education and Research (BMBF) to develop methane pyrolysis, a methane pyrolysis technology for producing climate-friendly hydrogen from natural gas. Here, methane or natural gas, which mainly consists of methane, is split directly into its components of hydrogen and solid carbon. The process uses comparatively little energy and, if it is run using electricity from renewable resources, is even CO2-free. Compared to other processes for emission-free hydrogen production, methane pyrolysis requires only around one-fifth as much electrical energy. A pilot reactor has been constructed in Ludwigshafen and is being started up.

We are working at high pressure on methane pyrolysis, because feasible solutions for clean hydrogen are needed. It is a particular challenge for us to help shape this path to a low carbon chemistry.“

Dieter Flick

Lead of the methane pyrolysis project

It is still unclear how the granular carbon from our pyrolysis will be used. In general, there are numerous markets for solid carbon, especially for high purity carbon, e.g. aliminium or steel industries.

Storage is also conceivable in principle, because our pyrolysis carbon is not a hazardous substance and can be stored in a stable manner. The various approaches are being investigated in the current project.

CO2-free hydrogen production: water electrolysis

More

In water electrolysis, water is split into hydrogen and oxygen using electricity. Since the energy here is introduced by electricity and not by an oxidation process (combustion), the electricity consumption is high.

BASF, in cooperation with Siemens Energy, is currently examining possibilities for the construction of a PEM (Proton Exchange Membrane) water electrolyzer with a capacity of 50 megawatts for the CO2-free production of hydrogen from water and electric power at the Ludwigshafen site. This CO2-free hydrogen is to be used primarily as a material in the Verbund, as well as to a limited extent for the market ramp-up of the mobility market in the Rhine-Neckar metropolitan region.

Storage technologies for CO2

More

Our goal is to prevent CO2 emissions from occurring in the first place. However, if this is not possible, we also want to investigate the use of storage processes for CO2. At the Antwerp site, BASF is planning to participate in one of the largest projects for storing CO2 under the North Sea (carbon capture and storage, CCS). Together with partners in the “Antwerp@C” consortium, this offers the possibility of avoiding the emission of more than 1 million metric tons of CO2 per year from the production of basic chemicals. A final investment decision is expected to be made in 2022.

CO2-free production: Methanol

More

Methanol is an important feedstock for the chemical industry. BASF researchers therefore worked on a new climate-friendly process for producing this basic chemical with the aim of not only reducing CO2 emissions, but also not emitting any CO2 throughout the entire process. Process development as part of the Carbon Management R&D program has been completed and BASF is currently reviewing all options for use.

The process

In BASF's new process, syngas is produced by partial oxidation of natural gas or biogas, which produces no CO2 emissions. While the process steps of methanol synthesis and distillation could be adopted almost unchanged, inventiveness was required when it came to combining and processing the waste gas streams generated here. They are first burned with pure oxygen (oxyfuel combustion). Gas washing using BASF's OASE® gas washing process then completely removes CO2 from the flue gas. To ensure that its carbon is not lost but is available again for methanol synthesis, the captured CO2 is fed back into the process. Additional hydrogen is required as a supplement, which should also be produced without CO2 emissions.