Who we are

Innovate with us!

BASF chemistry spans 10,000 R&D employees world wide, 280 universities and over 78,000 customers. We strive to be your partner of choice in Sustainable Innovation. Join our network of innovators!

Make a new bond with BASF - The Chemistry of Collaboration

Collaboration is about Connection, Connection is about people. Who or what can we help you find? #Letscreatechemistry

What type of bond are you looking for?

Related News Releases:

Date

Results: 2079

BASF Group releases preliminary figures for full year 2025

The BASF Group’s sales for the full year 2025 are expected to be €59.7 billion (2024: €61.4 billion, excluding discontinued Coatings operations). This is in line with the figure estimated by analysts on average (Vara: €59.6 billion). While volumes increased slightly in 2025, negative currency effects and slightly lower prices burdened sales development.

New digital solution at BASF Coatings to calculate the CO2 footprint of its product portfolio

BASF Coatings has launched a new digital solution to calculate the carbon footprint (Product Carbon Footprint, PCF) of its sales portfolio. The solution replaces an internally developed application that BASF Coatings has used for several years to provide reliable CO2 data to customers worldwide.

Eurofins and trinamiX launch Mobile Feed Analysis Solution for Equine Nutrition

Eurofins Agro Testing and trinamiX GmbH, announce a jointly developed mobile feed analysis solution for the equine sector that brings best-in-class forage testing directly to stables and pastures across Europe. This empowers stable owners, horse feed producers, equine nutritionists, forage dealers and veterinary professionals to make informed decisions based on real-time nutritional insights.

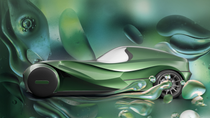

BASF Color Report: Green and gray redefine the 2025 automotive color landscape

In 2025, the global automotive color landscape reflects a clear shift toward individuality and nature-inspired aesthetics as consumers continue to move away from traditional favorites, as analyzed by BASF Coatings in the latest Color Report for Automotive OEM Coatings.

BASF Agricultural Solutions to acquire biological insect control group AgBiTech

BASF Agricultural Solutions has reached an agreement with private equity firm Paine Schwartz Partners and other shareholders to acquire its portfolio group, AgBiTech, which specializes in biological insect control solutions. BASF will assume full ownership of AgBiTech, including all assets such as portfolio, intellectual property rights, manufacturing operations, as well as research and development facilities, and personnel.