Media

Protective layers for noodles, muesli & co

Innovative BASF materials provide safe barriers against mineral oil residues in food packaging

- Safely packaged

Barrier solutions protect packaged foods against contaminants. - Razor-thin and durable

Coatings offer protection up to the end of the expiry period. - Selective barrier

Mineral oil residues are kept out, atmospheric oxygen and water vapor can pass through.

Shelves filled with colorful items as far as the eye can see: row upon row of shelves containing packs of muesli, rice, noodles and baking mixes. The deep freezers tempt customers with pizzas, vegetables and fillets of fish – well packaged in brightly colored boxes. Well designed paper packaging is essential for the food production sector because it is lightweight, space saving when stacked and can also be transported cost-effectively. At the same time, it protects the products against moisture, contamination and damage. Paper is the sustainable packaging material, particularly if produced from recycled fibers, however such fibers can contain mineral oils residues. Coating solutions from BASF protect the foods from these substances.

Cardboard packaging for food is often produced from re-cycled waste paper, such as newspapers. This paper contains, among other things, residues of newspaper printing inks which include mineral oils not approved for food contact. And that's exactly where the problem lies: the mineral oils cannot be completely removed in the recycling process and consequently enter the packaging. Mineral oils contain hydrocarbon compounds which can travel from the cardboard into the foods. Experts call this migration. This can happen even without direct contact between the cardboard and the food: some mineral oil residues already evaporate at room temperature. This mixture of gases disperses inside the packaging and the substances can be absorbed by the food. "Studies by the official Food Safety Authority of the Canton of Zurich have shown that about 30 percent of all migratable substances have entered the food after two months at room temperature," explains Heiko Diehl. The BASF Manager is responsible in the Paper Chemicals division for providing a support service for international brands who specify paper packaging for their foods. Especially products like flour, rice or baking mixes are affected because they can absorb larger amounts of the mineral oil constituents. "Once the contaminants have accumulated in the food, they can no longer be removed or made safe by washing or boiling," adds Diehl.

It is not only the industry that is aware of the potential health risk presented by mineral oils in food packaging. Mineral oil residues in foods and their effects are also being looked at by the attention of the competent supervisory authorities in Switzerland. Control examinations performed by the official scientists have detected high residues of these substances in human tissue. Dr. Konrad Grob of Zurich Food Safety Authority: "The use of cardboard for food packaging is so high that the inclusion of recycled material is unavoidable. No legally binding limits have yet been established, only official recommendations. With normal recycled cardboard, however, for most products stored for prolonged periods these values cannot be complied with without a barrier," says Grob.

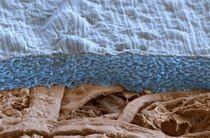

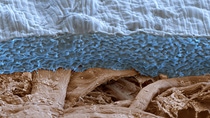

BASF has already developed various barrier solutions that are applied to the internal surface of the cardboard box. These extremely thin coatings are made from polymers, in other words macromolecules made up of many repeating smaller molecules. Barrier coatings that are only 10 to 15 micrometers thick – by comparison, a hair is 120 micrometers thick – already protect food from the contaminants for up to three years. Products like noodles that remain for an average of 15 to 24 months in the packages, are thereby reliably protected. "The most important requirement for the barriers is that the breakthrough time – which is the period until a barrier can become permeable and allow health hazardous substances to penetrate into the food – is longer than the shelf-life of the packaged product," explains Diehl.

"Our barrier coatings can be imagined as being like a close meshwork that allows only certain molecules to pass through," continues Diehl. Only very small molecules like water vapor, for example, can pass. Larger molecules like mineral oil residues cannot cross. In addition, the polar nature of the BASF barriers hinders the migration of the molecules.

Developing the barrier effect for large molecules was not the only challenge when designing the various coating solutions. Dr. Carmen Cimpeanu of BASF Materials and Systems Research explains: "The coating simultaneously has to be flexible enough to prevent fractures forming when folding the cardboard ensuring the barrier remains intact."

"Sustainable packaging is the current trend"

Interview with Michael Avemarg, Innovation Manager Materials at Europe's leading manufacturer of folding cartons and boxes, Van Genechten in Kempten (Germany). The company processes about 200,000 metric tons of cardboard annually.

What challenges will packaging manufacturers be facing in future?

Today, packaging has to protect not only against mechanical stress but also against contaminants. Laboratories have increasingly accurate analytical methods at their disposal and can track down undesired substances ever more effectively. New limits are being established which we as packaging manufacturers have to comply with. This also applies to mineral oil constituents in cardboard. We anticipate that strict limits will be imposed and have already modified our production lines. To develop optimal coating solutions for the manufacturing process, we are already cooperating with BASF and testing products in our plants. For the jointly developed WLC Food Safe coating based on BASF's plastic Ultramid, in September we won the German Packaging Prize 2013.

What will the packaging of the future look like?

The trend is moving mainly towards sustainable packaging. The use of renewable resources and recycling processes will play a major role in future. BASF's biobased coating variant ecovio, which we have already successfully tested in our plants, is moving in this direction. Additional functions such as higher heat resistance will also play an increasing role in packaging. New media are also becoming ever more present in the information applied to packages: there are more links to homepages or interactive competitions that consumers can use directly with their smartphones. And the packaging can be supplemented with virtual additional information, animated or even shown in 3D, by means of augmented reality functions.

Residues in recycled paper

Recycled cartonboard can contain mineral oil residues in amounts up to 1,000 milligrams per kilogram. To what extent foods packaged in this material are exposed to migration of these substances and what substances are actually involved are the subject of ongoing studies. The official Food Safety Authority of the Canton of Zurich already detected considerable amounts of mineral oils in cardboard packaging in 2010. The studies also showed that these substances accumulate in the body and can cause inflammations in the liver and lymph nodes. Not only recycled packaging, but also cardboard packaging made from fresh wood fibers is also at risk if stored in recycled paper boxes: the mineral oil constituents migrate through and thereby also enter the food.

Diferent solutions for one problem

In Europe alone, there are more than 1,000 manufacturers of cardboard packaging who operate different production processes and coating techniques depending on the plant size. BASF offers these customers a range of adapted coating solutions. Larger companies, for example, prefer extrusion processes in which a plastic melt is applied to the unfolded cartonboard. The BASF material Ultramid® made of the plastic polyamide is suitable for this process. Smaller packaging manufacturers, on the other hand, use printing processes to apply coatings. They can print a protective layer on the cardboard using specially developed aqueous acrylate dispersions. These dispersions can also be used by paper manufacturers for coating. The product ecovio® PS 1606, a polyester polylactic acid mixture has the advantage of being biodegradable and enabling compostable packaging. The packaging manufacturers can apply it to their cartonboard using extrusion processes.