Our water-based Acrodur® products are innovative, low-emission alternatives to conventional formaldehyde-based resins such as phenol, melamine or urea resins.

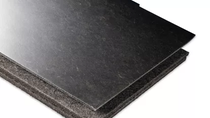

Under its Acrodur® brand, BASF offers innovative binders to reinforce natural, glass and synthetic fibers as well as cork and other particles. The purely water-based products from the Acrodur® family are a low-emission alternative to traditional formaldehyde-based urea, melamine or phenolic resins. Due to its outstanding binding properties Acrodur® enables to produce high-quality products for the automotive, furniture and construction industry.

Benefits of Acrodur®

Excellent profile of properties

Helps to promote sustainability

Wide processing options

Acrodur® for natural fibers in automotive

Performance meets sustainability

The weight of a car is crucial for its performance. Natural fibers enable the production of stable light-weight car parts and shape the way we drive tomorrow – when treated with Acrodur® by BASF.

Acrodur® in automotive

DLR and its "Next Generation Car" at a glance

Shaping future mobility together: DLR, BNP Brinkmann and BASF.

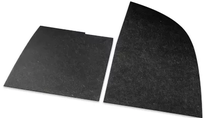

Lightweight technology plays a key role in automotive design, especially when it comes to e-mobility: only a subtle balance between net weight and power preserves the driving pleasure and reduces the energy consumption and, consequently, CO2 emissions. To create safe and sustainable components that reduce the weight of electric-driven vehicles, three future-driven players joined forces: BASF delivered Acrodur® for natural fibers and produced, together with BNP Brinkman, a tailor-made and extremely stable lightweight interior floor for one of DLR's "Next Generation Cars". This concept car combines latest automotive light-weight design approaches with innovative renewable materials and will shape tomorrow´s mobility.

From binder to floor mat :