Sustainability

FAQ

What is Eco-Efficiency Analysis?

The Eco-Efficiency Analysis developed by BASF is a tool for assessing products and processes on a comprehensive and comparative basis. The entire life cycle of a product is considered - this includes the environmental impact of the materials used, the use of the product by customers and end consumers as well as options for recycling and disposal.

In addition, the entire economic picture, costs for example, is assessed and the economic and ecological advantages and disadvantages of possible alternatives are compared. This means that products are not directly compared with one another on a mass or volume basis but rather their performance in applications such as "painting a square meter of furniture ".

How is the Eco-Efficiency Analysis used?

The Eco-Efficiency Analysis is a quantitative tool that helps in measuring sustainability.

It is a comprehensive, strategic instrument for decision makers and customers. Since ecological effects are assessed together with economic factors it ensures a balance between economy and ecology, two of the pillars of sustainable development.

How does the Eco-Efficiency Analysis work and which criteria are used?

The customer benefit is the starting point of each Eco-Efficiency Analysis. This is defined at the beginning of each analysis, together with the products or processes that can fulfill this customer benefit (alternatives). Afterwards the system boundaries of the study are defined, and life cycle inventories data are calculated for all the processes and products within the system boundaries. Thus it is possible to calculate the environmental impact of each single alternative taking into account several environmental categories (Life Cycle Assessment).

Eco-Efficient are such solutions (alternatives) that fulfill this customer benefit with lower environmental impact and costs than others.

In an Eco-Efficiency Analysis of tabs for automatic dish-washing, a newly developed product of BASF was compared with competing products. The question was: Which alternative is the most sustainable solution to perform 100 dish washing processes with an automatic dish-washer (Customer benefit)?

The analysis helps to answer questions like: How much energy is needed to do this? What emissions and waste result?

All processes that are required to fulfill the customer benefit are taken into account; this includes for example obtaining the raw materials necessary to produce the ingredients or the electricity needed.

The analysis showed, that the newly developed aminocarboxylates as one of the important ingredients of a tab, shows the lowest environmental burden along the whole life cycle compared to other alternatives which are using phosphates for this function. The lower environmental performance of the competing alternatives are linked to the higher use of resources, higher water emissions and higher amount of waste.

The analysis also takes the consumption behavior of end-users into account, as well as various recycling and disposal options.

The environmental impact is assessed with a range of categories:

- Raw materials consumption

- Water consumption

- Land use

- Human toxicity potential

- Eutrophication

- Acidification

- Ozone depletion

- Photochemical ozone creation

- Climate change

The “environmental fingerprint” shows strengths and weaknesses in each category for the alternative products or processes analyzed. This reflects the status quo but also indicates where there is potential for improvement.

The total environmental impact of each alternative is calculated from the “environmental fingerprint” by means of weighting factors, obtained from representative polls carried out by TNS Infratest on behalf of BASF.

Economic data are also compiled. All the various costs incurred in manufacturing or using a product is included in the calculation. By this way weak points and potential costs savings can be identified.

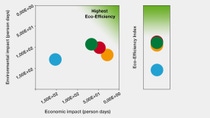

Economic and ecological data are plotted on a two-dimensional graph. The costs are shown on the horizontal axis and the environmental impact is shown on the vertical axis. The graph shows the eco-efficiency of a product or process compared to other products or processes. Further scenarios can be also analyzed.

What is the difference between Eco-Efficiency Analysis and other concepts like Life Cylce Inventory, Life Cycle Analysis or Carbon Footprint?

A Life Cycle Inventory (LCI) is an inventory of all relevant emissions, material and energy flows (inputs and outputs) along the life cycle of a product, including its disposal or recycling (cradle to grave). For single products or processes the system boundaries can be restricted to the gate of the factory, in this case the LCI is "cradle-to-gate".

A Life Cycle Assessment (LCA) encompasses the effects on the environment on the basis of the life cycle inventory. This is used to calculate the effects on the environment along the complete life cycle (production, use and disposal). The standards series ISO 14040 and 14044 gives general rules for conducting Life Cycle Assessments.

A CO2-balance or Carbon Footprint is part of the Life Cycle Assessment of a product and is an assessment of the product´s global warming potential.

Life Cycle Inventories and Life Cycle Assessments form the basis of every Eco-Efficiency Analysis. The Life Cycle Assessment analyzes exclusively the ecological effects of a product or process. The result yields a considerable amount of individual data sets. In the Eco-Efficiency Analysis the volume of data assessed is comparable to a LCA, but in the end there is a relatively tangible and compact representation which facilitates comparisons among different products and processes.

Furthermore, economic data are also taken into consideration for the analysis, resulting in a comprehensive assessment of ecological and economic issues.

LCI and LCA can be carried out for single products or processes, while eco-efficiency analyses always compare several alternative processes or products.

How are the criteria weighted?

The individual impacts for one alternative in each of the different impact categories are assessed with a normalization process and a subsequent aggregation with specific weighting factors. These state how strongly individual criteria flow into the overall environmental impact, i.e. how, for example, raw material consumption is weighted relative to greenhouse gas emissions. The weighting factors are obtained from the PEF (Product Environmental Footprint) project and reflect the importance which experts within this project attaches to the different environmental impacts.

What consequences can follow for end users?

The Eco-Efficiency Analysis can be used for comparison of different products that deliver the same user benefit. Moreover, it can compare more generations of the same product in order to show its environmental and economical improvement and the resulting advantages for end consumers.

Which products have been assessed with Eco-Efficiency Analyses?

So far more than 700 different BASF Eco-Efficiency Analyses have been completed, covering thousands of products and processes. Among others, products like floor coverings, packaging, insulation materials, shirts or automatic dishwashing tabs have been assessed.

- It was shown, that our biodegradable polymers in biowaste collection systems have clear benefits.

- An analysis carried out together with the Rhineland Palatinate regional government and the companies Gerolsteiner Sprudel, Hochwald-Sprudel and Schmalbach-Lubeca showed that for packaging and transport of mineral water PET reusable bottles are more eco-efficient than glass bottles.

- It was shown that insulation of a detached residential house is good for the environment and profitable for the landlord.

- It was calculated that automotive components made of polyamide help to save fuel and are more eco-efficient than aluminum components.

How was the Eco-Efficiency Analysis methodology created?

In 1996 BASF, along with Roland Berger Strategy Consultants and other partners, developed the Eco-Efficiency Analysis to assess the sustainability of BASF’s products and processes. The method was used for several BASF products before being made available for external customers. The method was updated 2017 by implementing new developments and standard methodologies from the PEF. The impact categories and assessment methods were harmonized according to the PEF methodology.

Has the method been validated?

Yes, the BASF Eco-Efficiency methodology was first validated in 2002 by the Rhineland Technical Surveillance Association (TÜV Rheinland). In 2008 TÜV Rheinland validated the Eco-Efficiency Analysis again, taking into account methodological updates. In 2009 BASF's Eco-Efficiency Analysis was awarded the internationally recognized seal of approval of the US NSF. In collaboration with various stakeholders and product safety experts at BASF Corporation, the NSF has defined standard requirements for Eco-Efficiency Analyses. The aim of NSF Protocol 352 is to ensure conclusiveness, objectivity and transparency for the different types of Eco-Efficiency Analyses. BASF's method has been validated under the requirements of this protocol.

The most recent validation was completed in 2019.

Is the Eco-Efficiency Analysis simply a greenwashing tool?

BASF has already been using the procedure since 1996 onwards and used it on numerous products and processes as a decision aid before it was made public. The majority of Eco-Efficiency Analysis are not communicated to the public. In its corporate guidelines, BASF has declared its commitment to constant improvements in safety, protection of health and environmental conservation. The Eco-Efficiency Analysis makes a strong contribution towards this goal. The strategic and organizational implementation of sustainability helps us to identify threats at an early stage and to develop new businesses for BASF.

What consequences follow Eco-Efficiency Analysis?

Typically, the following cases arise.

- The analysis confirms that a product or process already exhibits a high degree of eco-efficiency. This means that both costs and environmental impact are very low. In this case the company will note whether further improvements are possible and seek to further expand its market share. In addition, BASF or the client checks whether the results of the analysis can be used in sales.

- A product or process has inadequate eco-efficiency but it can be optimized. It can be easily read off from the eco-efficiency portfolio whether and to what extent it is the economic or the ecological component which must be improved. The task now is to optimize the existing product or process in order to achieve a higher degree of eco-efficiency. The detailed results of the Eco-Efficiency Analysis can be used to identify ecological and/or economic hot spots for the single processes.

- A product or process has a low eco-efficiency and cannot be optimized or the expenditure associated with this would be too high. In this case the company might back away from the product or process or substitute it by an alternative product. BASF has already made use of this possible course of action.

- A product at the research stage can be developed further in different ways. The alternative pathways can be analyzed with the Eco-Efficiency Analysis and the ecologically and economically most favorable variant is determined. In this way research resources can be purposefully deployed in favor of more eco-efficient products.