Who we are

Innovate with us!

BASF chemistry spans 10,000 R&D employees world wide, 280 universities and over 78,000 customers. We strive to be your partner of choice in Sustainable Innovation. Join our network of innovators!

Make a new bond with BASF - The Chemistry of Collaboration

Collaboration is about Connection, Connection is about people. Who or what can we help you find? #Letscreatechemistry

What type of bond are you looking for?

Innovation Challenges: Discover collaboration opportunities with BASF

Customer Needs

An expert opinion - Meet our Smart Scientists

Related News Releases:

Date

Results: 2001

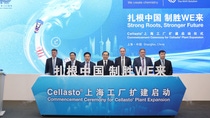

Cellasto® invests €60 million to establish a second plant in China

Shanghai, China – April 14, 2025 – Cellasto®, the world leader in Noise, Vibration and Harshness (NVH) components, is investing roughly €60 million to establish a second plant in Shanghai, China. This production expansion aims to capitalize on China’s booming electric vehicle market. The new facility will feature advanced mold lines, resulting in a capacity increase of nearly 70%, with operations expected to start in 2027. A commencement ceremony was held on April 14th to celebrate this expansion.

This News Release is only available in English.

This News Release is only available in English.

BASF Coatings sets new standard in end-to-end digital color solutions for body shops with Refinity®

In its cloud-based platform Refinity, BASF Coatings consolidates a comprehensive suite of digital business solutions for the automotive refinish industry, ensuring body shops worldwide can embrace sustainable digitalization with confidence. With the latest launch of a new color innovation and additional features, automotive refinish customers get access to the most advanced digital color experience, as well as business and training solutions seamlessly.

in-cosmetics Global 2025: BASF's Personal Care business wins BSB Innovation Prizes and Supplier Award

Amsterdam, Netherlands – April 9, 2025 – During in-cosmetics Global in Amsterdam, BASF's Personal Care business unit received three Innovation Prizes from the German consulting agency BSB. At the same time, the company was named the most popular supplier ranked by product searches on SpecialChem. The platform provides access to a free industry product database of cosmetic and personal care ingredients. “It’s an honor to be recognized for our commitment to developing and delivering cutting-edge, sustainable solutions that meet the evolving needs of our customers and consumers worldwide. This recognition fuels our passion to continue pushing the boundaries of what is possible in the personal care industry,” said Peter Weinert, Vice President, Business Management Personal Care Europe, Middle East, and Africa at BASF.

This News Release is only available in English.

This News Release is only available in English.

BASF Coatings recognized as 2024 Supplier of the Year winner by General Motors

General Motors presented BASF Coatings with a 2024 Supplier of the Year Award at GM’s 33rd annual Supplier of the Year event in Phoenix, Arizona, USA.

Auto Shanghai 2025: trinamiX showcases premium health and safety features for drivers and passengers

Ludwigshafen, Germany, April 8th, 2025 – trinamiX will present the Invisible Biometric Sensing Display at Auto Shanghai 2025. It detects occupants and tracks their vital signs using a camera and a laser dot projector installed behind the dashboard display. The technology supports a wide range of safety and comfort functions and works through an OLED screen, meaning it is completely invisible to the naked eye. The intelligent display solution, developed in collaboration with trinamiX’s partner Continental Automotive (UX), has been recognized as a 2025 CES Innovation Award Honoree in the "Vehicle Tech and Advanced Mobility" category.

This News Release is only available in English.

This News Release is only available in English.