Sustainability

Applications

Nanotechnology is a cross-sectional technology and the key to sustainable innovations in our growth areas.

Nanomaterials with new functionalities are, among other things, innovation drivers in the energy, health, electronics, housing and construction and automotive sectors.

Many products already successfully marketed for many years have only recently been shown by new analytical techniques to owe their decisive advantages to nanoscale components or structures. Today, however, nanotechnology enables us to develop and market new products very specifically.

UV filter

As the first UV filter with particle sizes smaller than 100 nanometers, Tinosorb® A2Bb was approved in 2014 in Europe for use in cosmetics such as sunscreen products. BASF’s highly efficient broadband filter protects both against UVB and UVAII radiation in wavelengths ranging from 290 to 340 nanometers. The absorption spectrum of this new UV filter is dependent on the particle size. With particle sizes of about 100 nanometers, optimum SPF performance can be achieved due to better skin coverage. As a result, a lower UV filter concentration is needed compared with conventional ingredients.

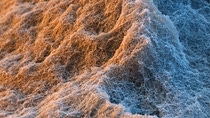

High-performance insulation materials

Nanopores provide the specific material characteristics in one of BASF’s new high-performance insulation material. Slentite™ is the first high-performance insulation panel based on polyurethane, which needs only half the space compared to traditional materials while offering the same insulation performance. Up to 90% of the volume of the organic aerogel consists of air-filled pores which have a diameter of only 50 to 100 nanometers. The high-performance insulation material can be used, for example, in the construction sector for old and new buildings.

Automotive clearcoat

iGloss® is a particularly resistant clearcoat for OEM coatings developed by BASF Coatings. When the clearcoat is cured, nanostructures form in the film through crosslinking and ensure that the coating permanently retains its scratch resistance and still looks new after many years.

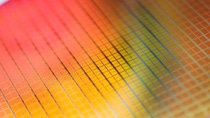

Polishing paste

From computers, through cell phones to coffee machines – many electronic devices are controlled using microchips. To ensure their perfect function, the surface of the wafers used to produce the microchips must be extremely smooth and defect-free. This is achieved by using a nanoparticle-containing polishing agent from the Planapur product range. Using a polishing pad and Planapur, the wafers are ground smooth several times during manufacture. To prevent their surface becoming scratched during this process, the grinding particles must be extremely fine and small. And nanoparticles fit the bill exactly.