Ludwigshafen

Special Edition BASF information

BASF information is the newspaper for BASF employees at the Ludwigshafen site. After the accident at the North Harbor on October 17, 2016, a special edition was published, which was also published on the Internet. The online version of this special edition was updated at regular intervals.

Dear Colleagues,

A tragic accident occurred at our site in Ludwigshafen on October 17. Two BASF firefighters and a barge crewman from an external company were killed; many other colleagues were injured. We are still deeply shocked and saddened by the fact that such an accident could happen.

Over the past few days, we have dedicated all our efforts to stabilizing the situation. I continue to face thoughts and feelings that I am sure many of you share: Deep sorrow and mourning for those who lost their lives. Heartfelt sympathy and condolences for their families and relatives. Wishes for a speedy recovery to all those injured in the accident, and hope and compassion that we send out to their families.

We feel tremendous gratitude for the emergency personnel and responders who risked their lives to protect and rescue. We are also very thankful for the solidarity and support we have received from customers, businesses, municipal politicians and partners. Our deep appreciation also goes to the crisis response team, which has worked around the clock to analyze and assess developments and make the right decisions with prudence and professionalism – coordinated with the appropriate authorities and municipalities. On behalf of all my fellow Executive Board Members, I thank all of you for your support. The accident raises many questions, and we still do not have answers to all of them. How could this happen? Did we make any mistakes? What do we learn from this? I understand when you ask: Why is everything taking so long? This is more than dissatisfying – for all of us; it truly puts our patience to the test. But we must proceed with caution and due care. It is vital that we stick to the facts and avoid speculation. We will not make premature statements before we have absolute certainty.

I assure you that we are working tirelessly and with great dedication to find out exactly what happened. We owe this to the grieving families, relatives, comrades and friends, the public and ourselves. I can also assure you that we will immediately inform you of any new findings, and that we will learn from this accident. Our neighbors are also posing questions to us; they have expectations, worries and concerns, and they expect answers. They trust that we will do the right thing. We must prove this on a daily basis in order to regain and strengthen that trust. This also requires that we continue to conduct thorough and honest analyses. One thing I can emphasize with absolute certainty: Safety is always the top priority at BASF. We all live by it. Every day. What is also clear after such an accident is that our safety measures are put to the test time and again – and we will continue to invest in safety. I am personally committed to this. Criticism has been voiced regarding some of our communication. Social media reactions and other reports inevitably begin to speculate while we are still working to obtain an overview of the situation, combat the damage and gather facts. This might give the impression that we are a step behind.

This point has also been raised in the feedback we received from you, dear colleagues, and it is a matter that we are certainly taking to heart. We are faced with the challenge of normalizing our daily operations. But the mourning and compassion will accompany us over the coming weeks and months. My thoughts are with those who perished, the injured, their families and their relatives.

Yours,

Kurt Bock

Chairman of the Board of Executive Directors of BASF SE

“Don’t Suppress the Grief”

Overview of the Site

BASF offers all employees and citizens the opportunity to express condolences and sympathy. As a charitable organization, the BASF Stiftung has set up a fund that will provide financial support to the victims and families in their time of need.

BASF has set up a place of peace and contemplation in front of the Gesellschaftshaus (Casino) on Anilinstraße, Ludwigshafen. A book of condolences is on display there, where everyone can express their sympathies at least until the end of this week. Moreover, there is the option of sending a condolence message via email to global.info@basf.com or as a personal letter to BASF SE, Carl-Bosch-Straße 38, 67056 Ludwigshafen, Germany. As a charitable organization, the BASF Stiftung has set up a fund that will provide financial support to the victims and families in their time of need. It also gives BASF employees the option of expressing their condolences to the victims and their families with a donation. Donations can be made to the BASF Stiftung using the keyword “Wir helfen” (We help). The donations are paid in full to the people affected and their family members.

The bank details are:

Commerzbank Ludwigshafen

IBAN: DE71 5454 0033 02061729 00

BIC: COBADEFFXXX.

“Pain Comes After The Shock”

Close Cooperation with the Authorities

“Employees at the site have come together.”

BASF information spoke to Sinischa Horvat, Chairman of the BASF SE Works Council, regarding his experiences and the Works Council's activities after the tragic accident.

Mr. Horvat, how do you perceive the current mood of the staff?

I feel that this tragic event has brought the employees at the site closer together. These days, many of us are pushing our personal limits. This is particularly true for the emergency personnel, but also for the colleagues from the various working groups and the Emergency Response Steering Committee (LAG). Our employees have questions that need answering.

What is your job as a member of the LAG?

I focus on the issue of care and support for the affected relatives and employees as well as on providing detailed information to the staff.

What kind of work does the Works Council do in a crisis situation such as this?

We have met several times since the events on Monday. We talk to the representatives to get a feel for the staff's concerns, and we are focusing on helping people come to terms with the tragedy. In the working groups, we discuss which lessons this teaches us for the future, in order to protect the staff even better.

Even outside the site premises, people feel connected to BASF. Residents and local politicians have voiced their opinions and show their sympathy.

The explosion at the North Harbor is a major blow to the Ludwigshafen site.

The site workforce is mourning the lost lives and grieves for the many injured colleagues. Large parts of the site's production plants have been affected. This is due to the fact that the raw materials supply and the entire site's logistics were severely impaired for an indefinite period by the loss of the supply routes in the area of the explosion.

Many colleagues are working around the clock to manage the Verbund so that the maximum number of plants can be safely supplied and start production again. The first step was to bring the steam cracker back online. The Steam Cracker II has been producing ethylene again since Friday of last week. Steam Cracker I will also resume operations shortly. The petroleum (naphtha) required for operation of the steam cracker will now be delivered through the Mannheim oil port on the Friesenheimer Island and then supplied directly to the site via the culvert. The North Harbor will not be available for an extended period due to damages caused by the explosion. Safety measures are still in effect for the entire area around the accident site.

What does this mean for logistics at the site?

Some materials will have to be supplied by trucks and railway, which entails a tremendous amount of effort. Verbund means proceeding in a coordinated manner and taking the big picture into account. Colleagues already proved that they are up to this task during the 2008 financial crisis. Participants in a Verbund coordination group discuss the next steps and the priorities on a daily basis. In addition to the supply and distribution of material flows, the entire factory logistics has to be completely redesigned. Road and truck transport as well as rail and tank cars now play a more important role in the supply of materials. The main truck entrance, Gate 15, is currently not operable. Instead, Gate 12 has been blocked for passenger car traffic and is now available for truck entry only. It is no wonder that in recent days, colleagues have been working around the clock to handle and eliminate truck back-ups at the site. Moreover, intense efforts are underway to reopen the intermodel transport terminal. Internal handling and coordination is one issue. BASF customers expect reliable delivery. They will be immediately notified when delivery cannot be guaranteed and force majeure has been declared (see info box). Currently, 23 plants are still not in operation and 45 plants are not operating at full capacity (as of October 24). “As soon as the accident site has been released, we will do everything to make damaged pipes operational again as fast as possible. A team of employees is already preparing the repair work. Despite the required haste, safety is the highest priority,” says Dr. Jürgen Nahstoll (ESI), responsible for the site's infrastructure.

More than four weeks after the explosion, BASF technical and safety experts are continuing to work with the authorities on securing and draining the pipelines at the accident site at the North Harbor. The aim of this work is to support the public prosecutor in his investigations and to rebuild the infrastructure at the accident site. The site fire department is also heavily involved, even though returning to the site where they lost three colleagues is not easy.

“We are working flat out to secure the damage site, so that evidence can be gathered at the site safely,” said Siegfried Fiedler (GUS/FO), Head of Onsite Emergency Response Operations (TEL). Currently working at the South fire station on planning and coordinating the safety measures, TEL is made up of BASF experts from the Plant Safety, Engineering and Technical Plant Inspection units and representatives of the production plants and site fire department. In this role, TEL acts as a link with the Southern Structure and Licensing Directorate (Struktur- und Genehmigungsdirektion Süd), which is responsible for approval and with which all safety concepts created by BASF are closely coordinated.

As well as police representatives, around twenty other BASF experts from the Pipe Racks, Port & Tank Farm and BASF Fire Department units are working on site in the piping area to secure, drain and flush pipelines for liquid gas and liquids. Later on, the work will also include safe dismantling of the pipelines that run through the accident site and measures to rebuild the piping network and get the North Harbor up and running again.

According to Fiedler, the fact that all activities are being conducted by BASF experts has been agreed with the investigating authorities, and the work is running smoothly and with great accommodation on both sides.

Five men from the site fire department are on site at all times during the securing and draining work to support the specialist units and plants in matters relating to fire prevention and respiratory and body protection.

No easy task – especially for those whose colleagues were affected by the explosion. “Needless to say, it was up to every individual whether he wanted to work at the accident site,” said Rolf Haselhorst (GUS/F), Head of the BASF fire department. “Everybody deals with grief in different ways, and we have to be understanding of that. We are encouraging all colleagues to get the help they need – be it from BASF’s own psychological advisors or by talking to their comrades,” said Haselhorst.

Extra measurement technology is being used at the accident site to make his team’s work at the North Harbor easier.

“The condolences expressed by BASF also did us good,” said Haselhorst. “From the quick support from colleagues in the site fire departments in Antwerp, Münster and Schwarzheide to the personal thanks given by BASF employees at the memorial events – my team and I have been very touched.”

An employee event on the accident at the North Harbor was held at the Feierabendhaus on October 26. Chairman of the Board of Executive Directors Dr. Kurt Bock, Member of the Board of Executive Directors Margret Suckale, Site Director Dr. Uwe Liebelt (ES), Dr. Beate Ehle, Head of the Environment, Health & Safety division (GU), Head of the site fire department, Rolf Haselhorst (GUS/F), and other members of the Emergency Response Steering Committee (LAG) were there to talk to employees and answer their questions. Here, BASF information summarizes some of the questions and answers.

A large number of customers and business partners worldwide have contacted BASF to express their sympathies following the explosion on the October 17. As well as messages of condolences, many also spontaneously offered their help and support. This included international companies, which are normally in competition with BASF.

BASF information has selected a few to show:

Stabilizing the Verbund

Since 1987, human biomonitoring has been taking place at BASF. Experts from the Occupational Medicine and Safety department (GUA) are measuring hazardous substances, specifically their decomposition products, in the employee’s urine or blood in order to recognize and evaluate their impact.

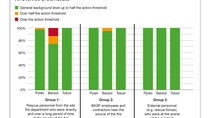

This was exactly what happened after the disaster at the North Harbor. The results are now available. BASF information spoke with Prof. Dr. Michael Bader (GUA/BC), Head of the Human Biomonitoring Laboratory at BASF, About the purpose of human biomonitoring, the results after the accident and about how to evaluate these results.