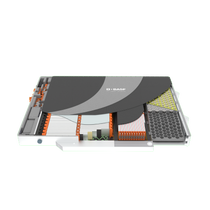

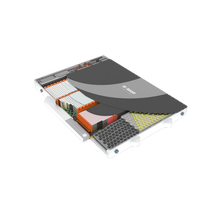

CHINAPLAS 2024: Innovative solid-state battery packs a model of lightweight, safe, & sustainable solutions for the eMobility industry

- Concept solid-state battery pack co-created by BASF, Yangtze River Delta Physics Research Center, and Welion New Energy Technology

- BASF at Chinaplas 2024: Hall 7.2 Booth C42, National Exhibition and Convention Center (Shanghai)

At CHINAPLAS 2024, BASF, Yangtze River Delta Physics Research Center (IOPLY) and Welion New Energy Technology (Welion) will present a new solid-state battery pack that showcases various solutions for eMobility, including lightweighting, thermal management, safety and sustainability. The concept solid-state battery pack features more than 20 advanced and high-performance material solutions, including Ultramid®, Elastoflex®, Elastan®, Ultradur®, Elastollan®, Elastocoat®, Cellasto®, and HED™ Cathode Active Material.

“As a global leading provider of high-performance materials, BASF has fully leveraged their research and development resources to collaboratively create this concept solid-state battery pack with us,” said Hong Li, the Chief Scientist of Welion New Technology. “We also developed a series of innovative product features and material technologies. Through this collaboration, we believe we can contribute to the next generation of solid-state power battery packs."

Lightweight materials help reduce energy usage, which extends driving range

The side cooling plate and cylinder cell holder in the battery pack are made of Ultramid — a material with an excellent strength-to-weight ratio. The Ultramid side cooling plate is 55% lighter than aluminum, while the Ultramid Expand innovative foamed polyamide cylinder cell holder is 25% lighter than conventional materials. As lightweighting leads to reduced energy usage, the driving range can be extended.

Enhanced thermal management boosts safety and lifespan of the battery

Improving the thermal management of batteries can effectively enhance their safety and service life. The upper cover of the battery pack is made of Ultramid composite and the thermal insulation pad is made of Elastoflex. Together, they enable the safe operation of batteries in high-temperature environments. The Ultramid side cooling plate effectively conducts heat and insulates electricity, improving the temperature uniformity of the battery compared with those made of aluminum.

High-strength materials ensure battery safety

To prevent the battery pack from being easily damaged in a vehicle collision, the side beam cavity filling made with Elastan is used to further improve its side impact protection. Elastan polyurethanes possess high strength and low density. They retain their lightweight properties while being impact-resistant. Accordingly, it enhances safety without adding significant weight.

“Solid-state batteries are promising next generation technology for traction batteries and energy storage systems, which are high energy density and provide superior safety performance. We are continually innovating materials for solid-state battery packs,” said Andy Postlethwaite, Senior Vice President, Performance Materials Asia Pacific.

Broad range of Cathode Active Materials to meet customer needs for performance and production scale-up

BASF is also a leading global supplier of advanced high-performance Cathode Active Materials (CAM) and supports the development of CAM for solid state batteries. HED™ Cathode Active Materials by BASF, by mitigating side reactions, offer good interfacial stability and are designed to optimal compatibility with solid electrolytes. This is resulting in high capacity, good rate performance, and cycling stability. In addition, BASF’s Cathode Active Materials are production line compatible and easy to scale up for immediate commercial volume supply.

Additionally, both the cylinder cell holder and pack upper cover are physically recyclable. Through these measures, BASF actively supports automotive companies in realizing their sustainability goals and diminishing carbon footprint.

“Since establishing the joint innovation center with BASF in July 2023, we have initiated collaboration between market leaders along the value chain and research institutes. By focusing on technological innovation in the eMobility and energy storage industries, we have invited the industries’ value chain partners, such as Welion New Energy, to develop the next generation of solid-state battery pack and drive the industry development," said Xiaotian Zhang, the President of IOPLY.

More technical details about the new solid-state battery pack will be shared during a tech talk on April 23 at CHINAPLAS 2024.

For press photos and updates on BASF at CHINAPLAS 2024, click here.

For the latest information on BASF at CHINAPLAS 2024, follow our BASF PM WeChat Channel:

About BASF

At BASF, we create chemistry for a sustainable future. We combine economic success with environmental protection and social responsibility. Around 112,000 employees in the BASF Group contribute to the success of our customers in nearly all sectors and almost every country in the world. Our portfolio comprises six segments: Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions. BASF generated sales of €68.9 billion in 2023. BASF shares are traded on the stock exchange in Frankfurt (BAS) and as American Depositary Receipts (BASFY) in the United States. Further information at www.basf.com.

About BASF’ Performance Materials division

BASF’s Performance Materials division is at the forefront of the much-needed sustainability transformation in plastics. Our products are co-created with customers around the globe to bring innovations to major industry sectors such as transportation, consumer goods, industrial applications, and construction. Our R&D focuses on all stages of the plastics journey: Make, Use and Recycle. The MAKE phase is about improving how plastics are made, from product design to the choice of raw materials and the manufacturing process itself. The USE phase enhances plastics’ strengths such as light weight, robustness, and thermal resistance. At the end of the product lifecycle, the RECYCLE phase looks at how to close the loop to achieve a circular economy. In 2023, the Performance Materials division achieved global sales of €7.2 billion. Join #ourplasticsjourney at: https://www.performance-materials.basf.com

Innovative solid-state battery pack a model_BM update.pdf/jcr:content.jpg)