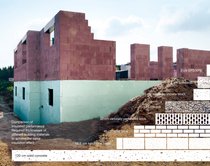

An extra layer for the climate

To limit the cost of heating and cooling, you need air – and that air needs to be enclosed.

We demonstrate how insulating materials build on this.

What do feathers, fur, and woolen sweaters have in common? They all seal in a lot of air between their fibers or pores. This is how they retain warmth in winter, because stationary air is a poor conductor of heat – and therefore a good form of insulation.

This simple rule of physics is also used by insulating materials made from polystyrene in sustainable construction. The synthetic material exists in the form of expandable polystyrene granulate (EPS) and extruded polystyrene (XPS). EPS is familiar to most people – as white Styropor®. In expanded form, it consists of thousands of air-filled beads, for which the granules have been foamed up to 50 times. Today, this classic is used mainly for packaging.

In construction, it is mostly the enhanced, gray Neopor® that is used for facade insulation. Here, heat radiation is also blocked by graphite particles. In this way, insulation panels with up to 20 percent better thermal insulation can be produced. With XPS, such as the green Styrodur®, the synthetic material is expanded, pressed into a strand, and cut into boards. This means the insulation withstands greater pressure and is less sensitive to moisture.

Both are good for the climate, whether produced conventionally or based on renewable raw materials. This is because thermal insulation made from polystyrene saves heat energy and therefore reduces CO2 emissions.