BASF in Greater China 2021

Business Development

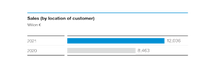

BASF posted sales of approximately €12 billion in 2021 to customers in Greater China. We continue to invest in advanced production and R&D facilities supporting the regional growth. Our investments enable us to deliver high quality products and solutions with customer proximity. We work closely with our suppliers, partners and customers to achieve joint success.

.png)

BASF Shanshan Batter Materials has built up the advanced R&D center at Da Changsha Site in Hunan.

Greater China drives growth in the global chemical industry. In the last two decades, BASF has invested more than €8 billion in Greater China (more than €11 billion with partners) to build a locally competitive production, marketing, sales, technical service, and innovation network that contributes to the profitable growth of the BASF Group.

The BASF Zhanjiang Verbund site will be built in phases. The first plants will produce engineering plastics and thermoplastic polyurethane (TPU). The first plant is scheduled to be operational by 2022 to serve the increasing needs of various growth industries in South China and throughout Asia. The whole Verbund site is slated for completion by 2030, and will be BASF's third largest site in the world.

BASF-YPC Company Limited (BYC), a 50-50 joint venture between BASF and Sinopec, is set to further expand its Verbund site in Nanjing, China. It will expand the capacity expansion of several downstream chemical plants and add a new tert-butyl acrylate plant to support the growing Chinese market. The new plant will be the first outside of Germany to use the BASF technology to meet the growing demand for specialty chemicals in China. The expanded and new plants are planned for 2023.

Addressing a growing electric market segment in the battery materials market, BASF partnered with Shanshan to create a new company, BASF Shanshan Battery Materials (BSBM). Shanshan is a leading lithium-ion battery materials supplier serving both the e-mobility and the consumer electronics market. The newly formed company has four sites in Hunan and Ningxia, with more than 1,600 employees. BSBM strengthens BASF’s position in Asia as it builds an integrated supply chain for customers across the globe. It increases annual global capacity to 160 kilotons by 2022 with further expansions underway.

BASF and China Resources Power made the first deal under the new renewable energy trading rules in Guangdong province.

Reinforcing its commitment to climate neutrality, BASF implemented a series of strategic initiatives to increase its use of renewable electricity. BASF joined the Renewable Direct Power Purchase (R-DPP) pilot trade in China, committing six BASF sites across Shanghai, Jiangsu and Guangdong province. Being the largest buyer in the Yangtze River Delta region, and the second-largest buyer in the Pearl River Delta region, this will secure 440,000 MWh of renewable electricity from various power producers through 2025.

BASF also secured 100% renewable electricity for its first plants at the Zhanjiang Verbund site. As the first and largest buyer of green power in the pilot trade of Jiangsu, the Nanjing Verbund site secured 107,000 MWh of the province’s renewable solar electricity to last through the end of 2022.

BASF opened new Catamold® Center of Excellence lab in Shanghai.

At BASF, we continue to invest in advanced production and R&D facilities to support the future growth.

To meet the high demand for solutions and products in the metal injection molding (MIM) market, BASF opened a new Center of Excellence laboratory for its Catamold® business in Shanghai. Catamold® are ready-to-use pellets for powder injection molding. The new facility will serve as the hub of expertise for solutions and products for the MIM market in Asia.

BASF-YPC became the first chemical enterprise in Nanjing to obtain the Advanced Authorized Economic Operator (AEO) in October. Advanced AEO Certification is the highest level of customs credit rating in international trade. With this, BASF-YPC is qualified to help partners and suppliers upgrade their supply chains to international standards.

2021 marked an important year for several BASF sites in China. BASF Specialty Chemicals in Nanjing (BSNJ), and BASF Polyurethanes in Chongqing (BPCC) celebrated their 10th anniversary with family and customer events. BSNJ is a wholly-owned BASF company that assumes a strategic and important role in BASF’s Flocculent for wastewater treatment and paper, specialty amines, and coating additives production network. BPCC was established to supply quality MDI, tapping into a growing market in China amid increasing customer needs for high-quality, environmental friendly chemicals and polymers.

In Guangdong, BASF Coatings (BCG) celebrated its 5th anniversary. It is the first automotive refinish coatings production site for BASF in Asia. The expansion of the BCG site reached a major EHS milestone of 500,000 safe construction hours in December since it started piling in June 2020. The new facility for automotive refinish coatings will start production in the first half of 2022.

BASF launched "Sustainability Covalence" with customers and partners in China to jointly promote sustainable growth.

At BASF, sustainable solutions are often born through cross-industry strategic partnerships.

BASF initiated and launched the “Sustainability Covalence” with 13 value chain partners to promote sustainable growth. Founding members take joint actions for low-carbon development, circular economy, and societal engagement across key industries in China. The founding members are leading local companies along the chemical value chain. Each partner will co-create with BASF on a carbon reduction project ranging from energy-efficient housing, safe and durable plastic applications, to low-carbon transportation and sustainable packaging solutions for food and beverages.

In 2021, BASF collaborated on battery and plastic recycling, better building materials, and influenced sustainable progress across industries.

BASF and Shanghai Jahwa United Co., Ltd signed the “Technological Innovation Cooperation Framework Agreement”. The partnership will accelerate relevant product development and innovation, while contributing to sustainable progress in China’s beauty and personal care industry.

BASF signed a strategic cooperation agreement with Shanghai COMIY BioTechnology Ltd. It allows BASF to penetrate the livestock industry and provide increasing solutions and business opportunities.

BASF and Shangahi Jahwa signed the "Technological Innovation Cooperation Framework Agreement".

As the leading chemical partner for all major automakers, BASF supports China's new energy vehicle industry with advanced battery materials, automotive coatings, engineering plastics and polyurethanes. These innovative solutions to enable the rapid development of e-mobility in China.

BASF established a strategic partnership with Contemporary Amperex Technology Co., Limited (CATL) on battery materials solutions, including cathode active materials (CAM) and battery recycling. The collaboration aims to develop a sustainable battery value chain while achieving carbon neutrality goals across Europe and Asia.

Additionally, BASF collaborated with SVOLT to further develop CAM, the supply of raw materials, and battery recycling for SVOLT’s battery cells. It will enhance the research and development capabilities of both companies in sustainable battery materials and strengthen both parties’ core competitiveness in both China and global markets.

BASF extended its long-term partnership with Fuyao Group to co-create innovative and sustainable automotive glass and functional exterior applications. BASF and SAIC Motor Passenger Vehicle Co. signed a strategic cooperation agreement to build a co-innovation laboratory to further bilateral cooperation in user-centric innovation for the automotive industry. The new co-innovation laboratory will explore automotive coating and interior solutions with ingenious features including light weight, safety and comfort, and design flexibility.

As a leading player in the automotive refinish coating market, BASF has taken proactive efforts to collaborate with industry partners to explore sustainable refinish coating solutions that respond to new emission standards. In 2021, BASF renewed the automotive refinish coating purchase agreement with BMW in China. Building on a long-standing and close collaboration, BASF continues to provide a complete one-stop solution for digital color tools, technical training courses, and value-added services that improve the painting process and site operational efficiency for BMW-authorized automotive body shops.

BASF’s refinish coatings brands Glasurit® and R-M® both won the bid of FAW Group’s aftermarket refinish coatings in 2021. This covers the full range of car brands such as Volkswagen, Audi, and Hongqi. BASF also invited all its partners along the value chain to work together to achieve the new volatile organic compounds (VOC) emission target, at the occasion of its Annual Dealers Conference in China held in Shanghai.

To serve customers in quick, ever-changing markets, BASF continues to digitize its businesses and enhance its e-commerce platforms.

BASF launched a new website for ‘Performance and Formulation Additives’ in April 2021. It is designed to provide faster and easier access to new additives. This fulfills increasing market needs for performance and sustainability and complies with stricter regulatory requirements.

BASF and strategic partner Xilong Scientific Co. Ltd. (Xilong) extended their long-term partnership to leverage digitalization and develop new sales channels. Xilong will provide BASF access to its digitalized integrated service platform for the chemical industry – ‘Youliao Web’, enabling BASF to launch a strong sales channel on the e-commerce platform.

To further strengthen its leading position in China’s commercial digitalization, BASF established its first real-time processing system. Based on Alibaba’s online order and payment system, the new system will replace its previous multi-step communication order-to-cash (OTC) process with an automatic data flow. This brings a faster online order experience to customers.

.jpg)

BASF collaborates with industry partners to explore sustainable refinish coating solutions.

BASF Venture Capital announced its investment in Bota Biosciences, Ltd. (Bota Bio), an industrial synthetic biotech company based in Hangzhou, China. Bota Bio, founded in 2019, is developing a proprietary next-generation biotechnology platform that enables sustainable and economical production of high-value products for a broad array of industrial applications. By investing in this promising young company, BASF strengthens its potential for innovation in the dynamic Asian markets.