Food packaging insights

Fast urbanization of the world has promoted the rapid development of food packaging industry. So what are the future trends for food packaging?

Food packaging has become an increasingly indispensable basic component of our daily life, which is closely related to the global urbanization trend. The reason for that is simple: when half of the world’s population lives in cities, while the cities are unable to provide the land and environment required for agricultural development, we’ll have to process and package our food and put them on supermarket shelves for people to purchase. That’s an increasingly convenient choice for people living a busy life in cities.

Good packaging can enhance the cleanness and freshness of food, while offering branding opportunities for food manufacturers. In addition, good food packaging can prevent food spoilage and extend shelf life, thereby reducing waste of food. According to statistics, up to 1.3 billion tons of food is wasted every year on a global scale, which can feed 1 billion people lacking in food.

According to information provided by World Packaging Organization (WPO), the turnover of global packaging industry is more than $500 billion, in which food packaging is a pillar area. However, food packaging is influenced by local food preferences in different countries and regions. Japanese consumers have a strong dislike towards incomplete packaging – even some insignificant crease on packaging could result in the unwanted destiny of supermarket food. Fish and seafood are an important part of the Japanese diet and must be kept fresh and prevented from spoilage. Normally a small bag of silica gel or starch polymer is put inside a food packaging to absorb moisture. However, European consumers share a different opinion – they are skeptical of moisture absorption agent and putting that in a packaging might just trigger their suspicion of the food itself.

Despite that regional preferences could result in different food packaging in different countries, we are still able to gain insight into several development trends in the food packaging industry.

It must be fresh

The demands made of packaging are high. Guaranteeing freshness and hygiene is a particular challenge, as foods must often cover great distances when travelling from their place of origin to supermarket shelves. Further time passes before they find their way into a shopping basket, and then again before they ultimately end up on the dining room table. Highly developed technology ensures packaging can keep products impeccably fresh and hygienic. The differing characteristics of the composite materials are combined to ensure the packaging is ideally suited to the food. The base of the packaging, for example, can be produced to have different characteristics than the lid or wrapping film.

Hard-wearing composites made of various materials are also well suited for use in what is known as Modified Atmosphere Packaging or MAP. With this technology, the air surrounding an edible product is replaced with a protective atmosphere specially tailored to the food. One example is a mixture of nitrogen and carbon dioxide. These slow-reacting gases replace oxygen, and slow the growth of germs, all without using any preservatives. To ensure the solution works properly, the packaging material must form an effective gas barrier. Otherwise, the valuable protective atmosphere would quickly be lost.

Safety first

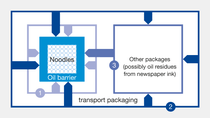

Potentially dangerous substances are not limited to the food, however – they can also be found at times in the packaging material itself. In 2010, researchers at the Zurich Food Safety Authority in Switzerland found that mineral oil residue contained in cardboard packaging was being transferred to foods. The main source of the problem was deemed to be ink used in newspaper printing, which found its way into the packaging via recycled paper. The residue traces detected also occasionally came from inks used to print the food packaging. These oil residues evaporate at room temperature, and can then be transferred to dry foods, such as pasta, semolina, rice, or cornflakes. This is even possible merely when the transportation packaging of the food contains recycled paper. Certain components of mineral oil are suspected of being carcinogens, according to the World Health Organization’s Joint Expert Committee on Food Additives, and the FAO.

BASF has already developed various barrier solutions that are applied to the internal surface of the cardboard box. These extremely thin coatings are made from polymers, in other words macromolecules made up of many repeating smaller molecules. Barrier coatings that are only 10 to 15 micrometers thick (one-tenth of the diameter of hair); however, they can effectively filter toxic mineral oil molecules of a larger size, while allowing smaller water molecules to pass through.

In China, the issue of food packaging printing ink pollution is just beginning to arouse people’s concern. As most of China’s food packaging is not printed with safe, edible ink, food safety experts remind consumers to notice whether barrier material is contained in food packaging when choosing the food.

China’s food manufacturers are showing more and more concern for the safety of food packaging, on the basis of meeting the needs of a fast-paced urban life. Recently, BASF worked with Zhuhai Fucheng Science and Technology Co., Ltd, one of the major producers of retort pouch and food packaging in China to develop a food cooking bag supporting efficient production. The bag can withstand high temperatures of disinfection, with excellent steam blocking performance. As no solvent is required in production process, it can realize zero solvent emissions as well as no solvent residue in the packing.

The mineral oil barrier protects food

Food packaging is often made of recycled paper fibers. This recycled paper packaging can contain newspaper ink, which researchers have identified as the main source of potentially harmful mineral oil residues in cartons. These oil residues evaporate at room temperature and can thus be transferred to dry foods that contain fats, such as biscuits.

Mineral oil residues can migrate from:

1. the inner side of contaminated primary packaging

2. contaminated outer packaging, for example, corrugated board packaging used to hold products during transportation

3. contaminated packages in close proximity, for example, on the supermarket shelf or in delivery trucks

Environmental efforts

Alongside freshness, increasing numbers of consumers want packaging that can be recycled. According to a survey of 6,000 consumers in ten different countries, carried out by Swedish carton manufacturer Tetra Pak, recyclable packaging is one of the public’s key priorities, as it is seen as kinder to the environment.

Consumers and legislative regulators are becoming increasingly concerned with packaging. The aim here is primarily to encourage the efficient use of resources. This trend is particularly noticeable in Europe. In the Netherlands, for example, a tax is applied to packaging manufacturers according to the average CO2 emissions of the materials used – 36 to 57 euro cents per kilogram for aluminum packaging, 6 euro cents for cardboard.

Demand for biodegradable renewable materials is also on the increase. For example, drink box and food container can be produced with biodegradable plastic, which contains a certain percentage of renewable raw materials. After use, the product can be disposed and used for compost together with food residue.

In China, as people’s awareness of environmental protection continues to grow, recyclable food in paper packaging is becoming more and more popular. According to statistics, paper packaging now accounts for about 40% of the packaging materials in China and the figure is likely to grow.

Intelligent packaging

Some high and new technologies have been introduced to the food packaging industry. The development of the Internet of things allows sensors, chips and electronic label printing to integrate into the traditional packaging industry. In years to come, ‘intelligent’ or ‘active’ packaging could help reduce food waste. This is a response to experts’ efforts around the world to come up with new ways to inform consumers about the perishability of food and to protect against spoiling. The new systems could display the state of a product and at the same time increase its lifespan with oxygen absorbers or special acids. As an example, American firm Sonoco is currently developing packaging with integrated microchips that collect information about the condition of a product, such as moisture and temperature. It raises the alarm when preprogrammed thresholds are exceeded or fall below target.

Of course, for business, cost is the first consideration in smart technology introduction. For some food with high added value such as premium health care products or highly demanding fresh food, it can be a sensible attempt to introduce intelligent packaging in order to further improve product added value and availability.