Copper chabazite: A milestone on the road to clean diesel engines

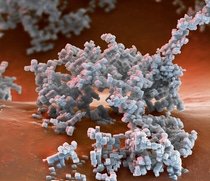

Thanks to their incredible catalytic abilities, copper chabazite zeolites, crystalline aluminosilicates, help to remove the majority of harmful nitrogen oxides from diesel engine exhaust gases.

Tighter exhaust gas requirements for vehicles, such as the standard US 2010 and the EURO 6 exhaust gas standard, are increasing demand for modern exhaust gas treatment catalysts. One of the key technologies used in vehicles with diesel engines is the so-called selective catalytic reduction (SCR) catalyst, which leverages BASF’s advanced copper chabazite zeolite technology. By developing the copper chabazite zeolite catalyst, an interdisciplinary team at BASF has achieved a significant milestone on the road to clean diesel engines.

The research behind the result

What is so special about the specialty zeolites and how did the team manage to develop and optimize them so quickly? Klaus Harth (research automotive catalysts at BASF) and Steffen Kerth (responsible for technology process catalysts at BASF) answer this and other questions.

Mr Harth, what exactly is a "specialty zeolite"?

Harth: Zeolites are aluminosilicates which naturally occur in various structures. Specialty zeolites, such as copper chabazite, are produced under increased pressure with the aid of organic substances. We are able to specifically produce structures with very high levels of activity, which are active at low temperatures. The copper ions, located inside the crystals, are the active catalysts in zeolite.

And how does this benefit SCR technology, Mr Kerth?

Kerth: The extraordinary catalytic activity of the copper chabazite zeolite occurs at very low exhaust gas temperatures and even remains efficient and stable at high temperatures. This means that considerably less nitric oxide is emitted in the exhaust system of diesel engines. When using our technology and the catalyst, our customers' vehicles then comply with the increasingly stringent exhaust gas requirements for diesel engines.

What was the greatest challenge faced in developing the zeolite?

Harth: The challenge was to develop a new catalyst technology in a very short amount of time that would significantly reduce nitric oxide emissions from diesel vehicles and to profitably implement the process in the construction of a large-scale system. The most important elements were synthesis development on a laboratory scale and initial scaling of the production of the chabazite zeolite. Our aim was to produce as efficiently as possible a synthesis of active zeolite catalyst which delivered not only high yields but most importantly maximum catalytic activity.

Kerth: The team also had to develop the corresponding procedures. We have managed to more than halve the number of process steps needed in the commercial production of zeolite, which significantly reduces manufacturing costs.