FWC™ – The new four-way conversion catalyst for gasoline engines

The FWC™ (Four-Way Conversion Catalyst) combines the functionality of a three-way conversion catalyst (TWC) with a filter on a single honeycomb. This new technology can remove particulate matter (PM), as well as carbon monoxide (CO), hydrocarbons (HC) and nitrogen oxides (NOx) from gasoline-engine exhaust – without curtailing engine performance or requiring additional space. This helps automakers meet strict new emissions regulations including Euro 6.

The research behind

Interview with Dr. Klaus Harth, responsible for automotive catalysts at BASF.

Mr. Harth, what's so special about the four-way catalyst?

Harth: We have further developed the three-way catalyst and optimized its cleaning effect. The new Four-Way Conversion catalyst, FWC for short, is a technology for gasoline driven vehicles. The catalyst removes not only the gaseous pollutants but also solids such as carbon particulates from tailpipe emissions. The compact four-way catalyst now combines all important properties in a single emission control catalyst. Compared with the three-way catalyst and downstream uncoated particulate filter, however, it needs much less space in the engine compartment.

Are there other advantages?

Harth: We have designed the FWC so that it builds up only low back pressure to the exhaust gas flowing through. This is an important aspect for the automotive manufacturers. Because a high back pressure increases the resistance to be overcome by the tailpipe emissions before they reach the exhaust system. If the back pressure is too high, this impairs the engine performance and worsens the carbon balance.

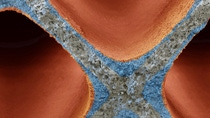

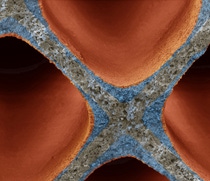

To keep the back pressure as low as possible, we have developed innovative coating processes. These allow us, for example, to specifically coat the porous internal walls of the monolith with the catalytically active material. Here, our many years of experience with catalyst technologies enable us to create tailor-made catalytic structures. This results in an enormously large surface area with a high catalytic activity. At the same time, a much smaller amount of noble metals needs to be incorporated in the four-way catalyst. Conversion rates of this four-way conversion catalyst are very high.

The porous monolith wall, however, also acts as a filter for the carbon particulate matter. The particles are retained there and are incinerated to carbon dioxide at high temperatures with the aid of the catalytic coating. The four-way conversion catalyst from BASF therefore does more than a conventional filter system with an uncoated filter. Since most of the carbon particulate matter is incinerated to carbon dioxide, the pores of the catalyst cannot become blocked – this preserves the long-term functionality of the unit.

And what kind of lifetime does a catalyst like this have?

Harth: The long-term stability has already been demonstrated in series of tests. Even after more than 160,000 kilometers driven, the four-way conversion catalyst still cleans the exhaust gas emissions perfectly. The new system was already presented in April 2013 and is now in the development and test phase with many automobile producers – always with a view to serial production. The four-way conversion catalyst helps automobile manufacturers to comply with the strict emissions regulations like the Euro 6 standard.