BASF in Greater China 2021

Environmental Protection, Health and Safety

Health and Safety

Protecting people and the environment is our top priority. Our core business – the development, production, processing, and transportation of chemicals – demands a responsible approach. We address environmental, health, and safety risks with a comprehensive Responsible Care Management System®. We expect our employees and partners to know the risks of working with our products,substances and plants and how to handle them responsibly.

Product safety is an important pillar of our commitment to Responsible Care. We are constantly working to guarantee that when our products are used correctly, they pose no risk to people or the environment. We aim to comply with all relevant national and international laws and regulations. BASF’s global requirements define the processes and procedures to ensure high product stewardship standards worldwide. Our specialists share expertise and best practices on product safety and stewardship, including internal guidelines and legal requirements on a regular basis.

BASF maintains and evaluates environmental, health, and safety data on all of its compounds and products in a global database, which serves as a foundation for product properties and hazard communication materials. These documents are made available to our employees, customers, and logistics partners so that they are well informed about the proper handling and use of potentially hazardous products. We use the Globally Harmonized System (GHS) to classify and label our products worldwide, by taking into consideration the legal requirements in each country.

We promote trusted, science-based product stewardship practices in Greater China by setting industry regulations and offering recommendations on guidelines for chemical safety. Our collaboration with local authorities through associations allows us to share our expertise on regulation and compliance management through various projects and events. In 2021, we proactively shared our experience and insights on hazardous chemicals and new chemical management with our upstream and downstream industry partners in China. These efforts include providing compliance and safety guidance to our suppliers in the management of regulatory change, exchanging hazardous chemical identification practices with our customers and service providers. This is done to prepare for the upcoming regulatory challenges and to achieve the goal of compliance throughout the value chain.

An operator is conducting routine inspection at the Caojing site.

Colleagues in Shanghai Engine Lab are measuring sensors and doing analytics verification before Selective Catalytic Reduction (SCR) testing.

Process safety is a critical part of ensuring safe, effective and sustainable production. We adhere to stringent safety standards throughout the planning, construction and operation of our plants worldwide. These comply with and, in some cases, exceed applicable local legal requirements. Our global guidelines provide the framework for the safe construction and operation of our plants, as well as the protection of people and the environment. Our experts have established a safety concept for each plant that takes into account the important issues of safety, health and environmental protection – from plant design to the end of the production phase and – specifies safety measures. Regular implementation checks ensure that all aspects of process safety comply with the safety concept and are always up-to-date.

We prepare a comprehensive mitigation plan for the management of energy and hazardous materials involved in our operations' storage, reaction, and physical processing. To maintain the highest level of safety at our plants throughout their entire life cycles, we ensure that our protection concepts, safety reviews and resulting safety measures are carried out at timely intervals in all of our plants based on risk potential opportunities and regulatory developments.

BASF’s global health and safety team takes proactive measures to promote, track and share process safety incidents all over the world by strengthening the regional collaboration. In Greater China, the safety team translates global incident reports into local languages on a monthly basis to share lessons learned and best practices across the region. We organized tailor-made process safety workshops and fundamental training for our employees based on specific topics such as regulatory compliance and pain points in sites. To more effectively resolve shortcomings and to improve risk detection and control at our operations, we use a globally uniform procedure for managing changes in regulatory requirements.

In 2021, BASF's Global Safety Days campaign, themed "We care. Stay Safe!" was held to raise employee risk awareness, with a particular emphasis on process safety incident (PSI) prevention and machinery and equipment operating safety. In Greater China, 12,788 employees and contractors from over 30 sites participated in 182 activities related to the campaign.

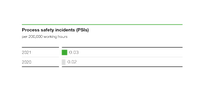

Tracking process safety incidents is also a key performance indicator. BASF’s global goal is to reduce the safety incidents rate to less than 0.1 per 200,000 working hours by 2025. In 2021, Greater China’s process safety incident rate was 0.03 per 200,000 working hours. Greater China’s success can be attributed to our focus on continuous improvement of incident management by investigating high severity / high severity potential incidents, analyzing root causes, and implementing changes as needed.

%20.png)

Keeping chemicals safe on the road is in everyone’s best interest. That is why, in Greater China, we are steadily improving China’s domestic chemical transportation – we assess the road safety of our carriers, support internal business on chemical transportation route risk assessments, such as Benzene, Propylene, etc. and advise on new regulations to improve transportation safety. We advocate for and advise Chinese authorities and chemical associations, including the Association of International Chemical Manufacturers (AICM), the China Petroleum and Chemical Industry Federation (CPCIF), the China Storage & Distribution Association, and the National Dangerous Goods Road Transportation Alliance.

We conduct routine examination of trucks to ensure they are in a safe condition when entering and leaving the site.

Topics include new regulations or standards for drafting the “Regulations Concerning Road Transport of Dangerous Goods” and “General Rules for Hazardous Chemical Storage”.

We helped establish the Chemical Road Safety Assessment System (CRSAS) in 2018. CRSAS is a network of logistic partners dedicated to ensuring road safety through assessments. In 2021, CRSAS membership increased to 40 chemical companies and 338 logistics companies. The network also held six public online training sessions, reaching over 800 people.

In 2021, BASF received the official appreciation letters and recognition from the People’s Republic of China’s Ministry of Transport for its efforts and contributions to safety improvement in China’s chemical industry. The National Dangerous Goods Transportation Service Alliance also presented BASF with the “Excellence Contribution Award to China Chemical Road Transportation Safety Sustainable Development”.

Fire prevention inspections were carried out regularly at sites to keep the firefighting systems in good working order.

The constant theme for emergency response management is disaster prevention, reduction, and relief. Ensuring effective preparedness for emergency response is our goal. We have a well-maintained incident management system and properly engage the emergency response structures based on the situation to minimize the impact scope in the event of an emergency.

Fire prevention inspections at production sites were carried out regularly by emergency response experts to keep the firefighting systems in good working order. The high-competence emergency response team responds quickly to any incident that occurs in operations, transportation, and along the supply chain.

Throughout 2021, BASF sites in Greater China completed emergency response training and drills based on actual scenarios in a variety of forms. We continue to strengthen our collaboration with the Ministry of Emergency Management of the People’s Republic of China to support emergency management in China, particularly with regard to standard formulation.

BASF chairs the emergency response working group of the Responsible Care Committee of CPCIF and the Responsible Care Committee of AICM. We proactively leverage these two platforms to share our best practices in emergency response management. We also support CPCIF in developing the “Implementing Rule of Responsible Care – Community Awareness / Emergency Response”.

BASF Shanghai Pudong Innovation Park was honored once again by the local fire authority for excellent firefighting management in 2021. BASF received the recognition for the fifth consecutive year.

In 2021, we took a proactive approach to epidemic prevention and implemented timely precautionary measures to safeguard the health of our employees and contractors, under the guidance of the Country Incident Management Team.

We protect our employees, sites, plants and company know-how against third-party interference. BASF uses applies the “security by design” principle to critically review and optimize IT applications from a cybersecurity standpoint as early as the design phase. This includes, for example, analyzing potential security risks in the communities surrounding our production sites and addressing in-depth issues of cybersecurity and information security.

BASF protects itself with a comprehensive program that is constantly working to prevent, detect, and react to cybersecurity incidents as technology advances. By establishing a global Cyber Security Defense Center, BASF has made its cybersecurity experts available around the clock, including teams in Greater China. To protect investments and strategic plans, we analyze associated potential risks and define appropriate safety and security concepts. We continued to improve our ability to prevent, detect and react to security incidents through various measures and investment projects. This includes conducting comprehensive analyses of potential risks and defining appropriate protection measures.

We want to raise employee awareness of cybersecurity and equip them with the tools necessary to defend themselves effectively. Throughout 2021, we organized a number of information-sharing activities to raise employees’ risk awareness. It included interactive online training and exchange of case-studies. We further defined mandatory requirements for conducting audits and ensuring process compliance when dealing with sensitive information. We are also anticipating and enacting new measures to protect personal information.

To prevent work related accidents, we promote risk-conscious behavior and safe working practices, learning from incidents and engaging in regular discourse. We constantly refine and enhance our requirements and training.

The annual Greater China EHS Awareness & Knowledge Competition (GEAR) program was held for the second time to encourage employees to learn about the importance of safety through competition. Over 4,200 BASF workers and contractors from 30 BASF plants and offices across Greater China took part in the program. Meanwhile, we expanded our EHS knowledge database to include over 105 topics and 1,650 questions to improve staff training effectiveness.

The optimization of the work permit system is critical to ensure compliance with both global requirements and national standards. To meet the latest BASF global requirements on work permits were promulgated and implemented in January 2021 and GB30871, a national standard specifying the requirements for special operations in China, a working group was set up to optimize work permit process. The updated, recommended processes and templates were communicated online to relevant personnel from Greater China sites.

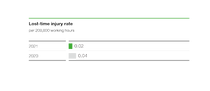

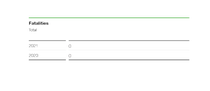

BASF aims to reduce the worldwide lost-time injury rate to no more than 0.1 per 200,000 working hours by 2025. In 2021, we recorded 0.02 work-related lost-time injuries per 200,000 working hours and no fatalities at any BASF sites in Greater China.

In conjunction with the “Recharge Yourself” global campaign, a trekking event was held at the Rudong site, Jiangsu province.

At BASF, our commitment to providing a safe, healthy work environment is unwavering. BASF’s global corporate health management team serves to promote and maintain the health and productivity of our employees. A directive specifies global occupational health standards, which are applied by a network of specialists around the world.

We measure our performance in health protection using the Health Performance Index (HPI). The HPI comprises five components: recognized occupational diseases, medical emergency preparedness, first aid, preventive medicine, and health promotion. Each component contributes a maximum of 0.2 to the total score, meaning that the highest possible score is 1.0. Every year, we strive to achieve a value greater than 0.9. With an HPI of 0.96, we once again reached the goal in 2021 (2020: 0.92).

In 2021, our team in Greater China continued to make great efforts in carrying out epidemic prevention at our sites. For example, at the BASF Shanghai Pudong Innovation Park, we distributed appropriate masks every week, disinfected all public areas and cleaned the air conditioning systems regularly, took daily temperatures of everyone entering the site and enforced social distancing with special seating arrangements. BASF also provided assistance to employees and contractors, including Shanghai-based BASF employees with foreign passports and their family members, to get vaccinated through weekly commutes to hospitals, on-site services, and group vaccinations in hospitals. BASF constantly monitored the impact due to local transmission, assisted sites and offices with control measures and provided staff with weekly updates.

We launched the ‘Recharge Yourself’ global campaign with a focus on regeneration and personal health. In Greater China, we developed our own tailor-made health promotion programs, such as ‘Go for Fitness’, ‘Management of Chronic Diseases’, ‘Health Diet’, ‘Prevention of Heat Stress’, ‘Mental Health Survey’, and ‘Summer and Health’ among others.