Small beads for long distances

A more comfortable jog:

Unique foamed material delivers spring and cushioning properties.

High rebound effect:

Special air cell structure of welded foam beads returns energy to a great extent.

Light and flexible:

Expanded thermoplastic polyurethane opens up new applications.

The world is on the move. To keep physically fit, more and more people jog for miles, across fields and along roadways. You can go running just about anywhere. All you need is comfortable apparel and a pair of running shoes. The global sports equipment industry is profiting from an increased enthusiasm for running: Worldwide, runners spend an estimated €15 billion on their equipment.

Customers place top priority on good footwear. Even people who only go jogging occasionally now look for lightweight soles that provide optimal shock absorption and enhanced running comfort.

Today’s sports shoes are genuine high-tech products compared to previous versions: The many different materials used to manufacture the shoes make them lightweight and stable. These materials enable the shoes to be tailored precisely to suite the style of running, the customer’s expectations and the various running disciplines. All this can be confirmed with a look around the development laboratories of sports shoe manufacturers: Test subjects run over sensitive pressure measuring plates which analyze and evaluate every step. High-speed cameras film the movement patterns and the heel-to-toe motion of the feet in the tiniest detail. All this information goes into the subsequent shoe design, which enables athletes to achieve new personal bests – and also offers recreational runners optimal running conditions.

Manufacturers are permanently on the lookout for cutting edge technologies and innovative materials. adidas is also constantly further developing its running shoes. The company, headquartered in Herzogenaurach, Germany, has been supported by BASF materials experts for more than 20 years. Using BASF’s new foam InfinergyTM, adidas has now developed the Energy Boost, a thoroughly new running shoe with unique spring and cushioning properties. Its outstanding feature is the midsole, the central element of every running shoe. It is made from a new particle foam which absorbs the shock impact on the foot during jogging, while simultaneously cushioning the foot. The high rebound effect of the material provides the runner with an energy return not offered by any other running shoe.

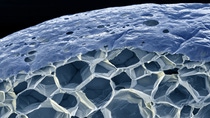

Infinergy is made of expanded thermoplastic polyurethane, in short E-TPU. “E-TPU is manufactured by foaming the starting material, TPU granules,” explains Dr. Uwe Keppeler, material and process developer at BASF. “After pretreatment with pressure and heat, the individual granules measuring up to five millimeters each are blown up like popcorn.” In the process, its volume increases tenfold to produce oval foam beads with tiny, closed gas bubbles inside. “These sealed air cells make the lightweight foam beads very elastic and provide the desired rebound effect. The individual beads can be imagined as being like tiny footballs: The more air they contain, the better they bounce and rebound back,” says BASF research scientist Dr. Frank Prissok.

For every midsole, adidas needs about 2,500 of these small beads. To convert them into the desired form, they are treated with hot steam, a process in which the outmost layer of the beads melts slightly, causing them to bond into a stable shape. The internal air cell structure remains unaffected by this process.

A midsole made from Infinergy can be compressed to an extreme degree: by about half of its volume at a pressure of two bar. This property is particularly effective in absorbing the shock impact on the foot. As soon as the compressive impulse subsides, the foam returns to its original shape at lightning speed. The sole therefore absorbs the runner’s energy, but then returns a large amount to the runner. This rebound elasticity of the individual Infinergy beads literally transforms the running shoes into energy stores: “When the foot is pushed off the ground, the force expended is largely returned to the athlete. This results in completely new and improved running behavior. Many runners have told us that the shoe feels like it is almost alive,” explains Gerd Manz, Senior Innovation Director Global Brands at adidas. Another advantage of BASF’s specialty foam: It’s not only lightweight, but it also remains elastic over a wide temperature range. The particles make sure that the Energy Boost shoe also retains its positive properties at minus 20 degrees Celsius. “The running characteristics are therefore the same at frosty temperatures as at summerlike 30 degrees Celsius,” says Manz.

Material for unpuncturable tires

Very lightweight and elastic - these special properties make Infinergy a material with a wide range of applications.

Some of these are currently in the trial phase. Others may still be a long way off, but are certainly feasible: in the future, BASF’s foam could, for example, make the "flat-less" bicycle tire that many cyclists are dreaming of become a reality. Infinergy is also potentially suitable as flooring for running tracks. For the automotive industry manufacturers, who are always searching for lightweight and robust materials, BASF’s specialty foam could also open up completely new opportunities.

A bed for cows

Cows like soft surfaces - and the more often and longer the animals lie down, the better the milk. Ruminants should rest for at least 12 hours, since the blood supply to the udder is optimal during their resting period – which increases milk production. Cows are also picky creatures and won’t lie down on just any surface. Cows’ mattresses made of the innovative particle foam Infinergy are not only soft, but also extremely tough and remain elastic even after prolonged use. BASF’s new plastic combines both properties for the first time. The mats have already passed the loading test performed by the German Agricultural Society (DLG) in which they were loaded 100,000 times with a weight of one metric ton. Practical tests are now underway in a trial cowshed of the DLG.

Buffer zone in the children’s jungle

Crossing rivers on wobbling stones, balancing over suspended bridges and traversing ravines. Children with rheumatic diseases can once again experience spectacular adventure sports in less hazardous terrain: at the Movement Park of the Rheumatism Clinic for Children in Garmisch-Partenkirchen, Germany, opened in the fall of 2012 in cooperation with the Munich company Innovationsmanufaktur. Here, the young patients can again have fun with sports and movement. Studies have shown that rheumatism and sport are not mutually exclusive - on the contrary, targeted training can promote the physical fitness. Particularly important, however, is that the children’s joints should not be overstrained. This is why a well cushioned floor and soft elements play a major role. BASF’s novel material Infinergy provides optimal properties for the “jungle zone” of the Movement Park. With its good rebound characteristics, the floor can soften falls very effectively. The material is also very weather resistant and tough - making it ideal for outdoor applications.